Change Language :

e-loop® - the service loop alternative

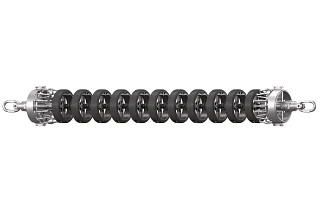

This is how the e-loop® is constructed

1) The inner body consists of four injection moulded parts. Two of these form the crossbar in the chain link and are screwed together (so that they cannot be lost). The screw connection clamps them onto the hauling rope.

2) Outer protectors made of impact-absorbing PU protector ensure that the energy chain and the cable are protected in the event of hard impacts.

- The individual chain links are clamped onto the high-strength hauling rope. The rope itself is a plastic fibre rope and has a permissible tensile load of 50 kN.

- The mounting brackets of the e-loop® are stable steel mounting brackets. The plastic fibre rope, which absorbs the entire tensile force of the e-loop®, is integrated into them.

e-loop® Product selection

Dynamic, full-webbed | for almost all applications

| Part No. | Inner width Bi: [mm] | Outer width Ba [mm] | Bend radius [mm] | Cable diameter [mm] | Fill weight [kN] |

|---|---|---|---|---|---|

| ELP.220.01.D | 150 | 220 | 380 | 38 | 4 |

| ELP.300.01.D | 230 | 300 | 500 | 75 | 7 |

| ELP.430.01.D | 360 | 430 | 680 | 108 | 11 |

| ELP.TD.300 | 230 | 300 | 500 | 75 | 50 |

Static, semi-rigid | for purely static cable routing

| Part No. | Inner width Bi: [mm] | Outer width Ba [mm] | Bend radius [mm] | Cable diameter [mm] | Fill weight [kN] |

|---|---|---|---|---|---|

| ELP.220.01.S | 150 | 220 | 175 | 38 | 4 |

| ELP.300.01.S | 230 | 300 | 210 | 75 | 7 |

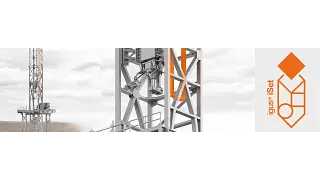

The most fascinating projects with e-loop® service loop

Buy the e-loop as a complete set

Order the e-loop in just three clicks. Save a lot of time and significantly reduce costs.

FAQ - Frequently asked questions for e-loop®

A service loop is used to feed cables and hoses in suspended applications, e.g. as a power supply to the top drive. To this end, cables are often cast together in a dress pack.

To ensure that heavy cables with large cross-sections can be reliably guided in hanging applications, igus has developed the e-loop as an alternative to the service loop. The energy supply system is a round, three-dimensional modular system that can move strain-relieved cables with a defined bend radius. The cables can be used individually and replaced during maintenance. The chain links are also replaceable at any time.

The new energy supply system from igus is built around a high-tensile plastic rope that absorbs the tensile forces of the cables. The rope is made of a synthetic plastic fibre, so it is shatter-proof, weather-resistant, flexible, and corrosion-free.

Unhook, lay down, unscrew, exchange cable(s), screw shut, remount. That's all it takes regarding maintenance thanks to the simple modular setup of the energy chain. For the rarest of cases you should always have a replacement chain at hand to avoid downtime.

igus® supplies the e-loop® just as you want it: either fully assembled or ready-made, on drums or pallets. There is a defined thread at the end of the e-loop for additional mounting. Our installation team is happy to take care of the assembly.

The individual chain links are all secured with screw connections so that no components can fall off.