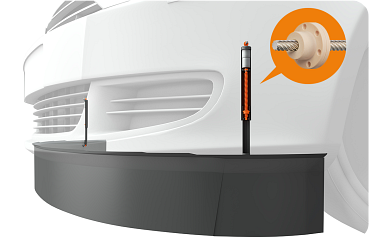

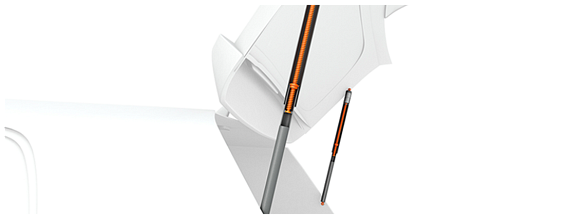

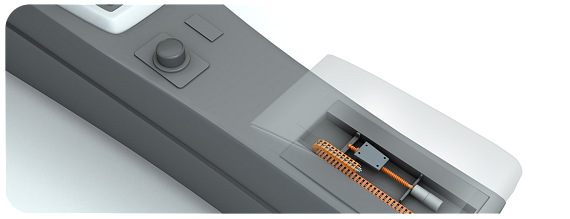

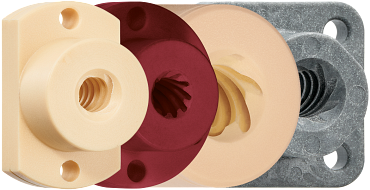

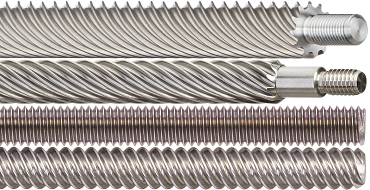

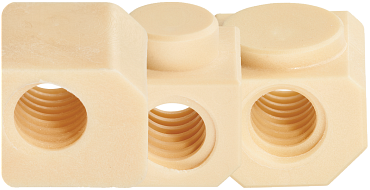

With the dryspin lead screw technology, it is easy to design individual lead screw nuts and lead screws exactly according to the wishes of the customer. Our experts will be happy to help you choose the right lead screw drive and will ensure that deliver times are short. The wide choice of materials and complete absence of a need for lubrication or maintenance mean that the lead screw drives can be used in almost any area of the automotive industry. They are ideal for small installation spaces and operate almost silently even when the drive torque is low. Uncomplicated integration into your vehicle or assembly is also an aspect that speaks in favour of the cost-effective alternative to conventional lead screw drives made of metal.

Monday to Friday from 8am - 8pm.

24h