Contact

igus® Ltd.

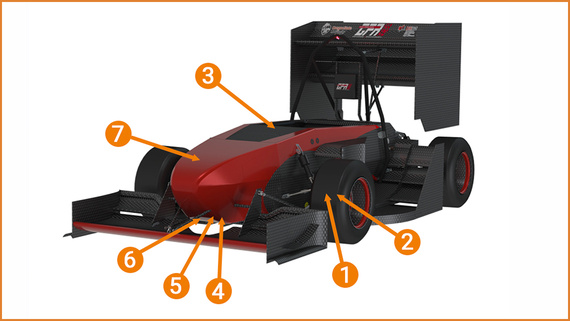

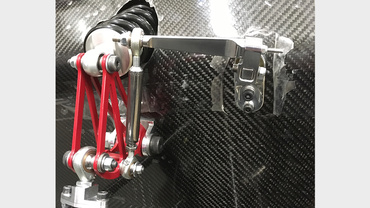

The suspension system uses slide bearings made of iglidur P and Z and igubal spherical bearings. They are suitable for formula cars because they work reliably even under variable, oscillating loads while also saving valuable weight.

The students use plain bearings made of iglidur X in the steering system. They take the place of large, heavy metal bearings that require a special assembly tool. They also require no maintenance and can cope with even difficult environmental conditions such as moisture.