Change Language :

iglidur® Q290 - material data

The most important specifications at a glance

The strengths of iglidur Q290 are evident in medium to high dynamic loads: In robust pivoting applications, e.g. in agricultural or construction machinery, and specifically on "soft" shafts (e.g. galvanised), excellent service lives are achieved - for shaft and bearing.

| Descriptive technical specifications | ||

|---|---|---|

| Wear resistance at +23°C | - 🟧 🟧 🟧 🟧 ⬜️ + | More information on wear resistance |

| Wear resistance at +90°C | - 🟧 🟧 🟧 ⬜️ ⬜️ + | |

| Wear resistance at +150°C | - 🟧 🟧 ⬜️ ⬜️ ⬜️ + | |

| Slide property | - 🟧 🟧 🟧 🟧 ⬜️ + | Coefficient of friction, dynamic, against steel, dry: 0.14 - 0.26 |

| Wear resistance under water | - 🟧 ⬜️ ⬜️ ⬜️ ⬜️ + | |

| Media resistance | - 🟧 🟧 🟧 ⬜️ ⬜️ + | More information on media resistance |

| Resistant to edge pressures | - 🟧 🟧 🟧 🟧 🟧 + | |

| Resistant to shock and impact loads | - 🟧 🟧 🟧 🟧 🟧 + | |

| Dirt resistance | - 🟧 🟧 🟧 🟧 🟧 + |

Temperatures

The long-term upper temperature limit of +140°C permits broad use e.g. in applications typical for the agricultural, utility vehicle or construction equipment sectors. For temperatures over +80°C an additional locating spigot is required.

Temperatures, coefficient of thermal expansion

| min. application temperature | Upper application temperature, long-term | Upper application temperature, short-term | In addition secure axially from |

|---|---|---|---|

| -40°C | +140°C | +180°C | +80°C |

Permissible surface speeds

The typical applications for iglidur Q290 plain bearings are medium to highly loaded pivoting movements with rather low speeds. Irrespective of this, high maximum speeds can certainly be achieved. The speeds given in the table are limit values for low bearing loads. They say nothing about the wear resistance at these parameters.

Surface speeds of various iglidur materials

| Maximum surface speeds [m/s] | Rotating | Oscillating | linear |

|---|---|---|---|

| Long-term | 0.8 | 0.6 | 1.0 |

| Short-term | 2.0 | 1.4 | 2.0 |

Permissible pv values

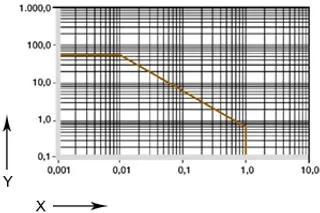

Diagram 01: Permitted pv values for iglidur Q290 plain bearings in dry operation against a steel shaft, at +20°C, installed in a steel housing

X = surface speed [m/s]

Y = pressure [MPa]

Mechanical properties

With increasing temperatures, the compressive strength of iglidur Q290 plain bearings decreases. Diagram 02 shows this inverse relationship. At the short-term permitted application temperature of +180°C, the permitted surface pressure is still more than 10MPa. The maximum recommended surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this. Diagram 03 shows the elastic deformation of iglidur Q290 under radial loads.

Friction and wear

Please note that a mating surface that is too rough will increase the friction. The coefficient of friction of iglidur Q290 also increases with increasing speed (diagram 04). In contrast, the coefficient of friction drops continually with the radial load, as illustrated by diagram 05.

Coefficient of friction against steel (Ra = 1μm, 50 HRC):

| iglidur Q290 | dry | Greases | Oil | Water |

|---|---|---|---|---|

| Coefficient of friction μ | 0.14 - 0.26 | 0.09 | 0.04 | 0.04 |

Shaft materials

Generally, the use of hardened shafts is recommended for higher loads starting at approximately 10MPa. This is, however, often not the case in practice, especially in connection with corrosion-resistant coating methods. Thus, great importance is attached to the iglidur Q290 material in such applications. Diagram 08 shows this very clearly in connection with galvanised shafts.

<a 0="[" 1="o" 2="b" 3="j" 4="e" 5="c" 6="t" 7=" " 8="O" 9="b" 10="j" 11="e" 12="c" 13="t" 14="]" href="/de-de/website/gleitlager/wiki/wellenwerkstoffe" uuid="98ebc0b0-39f6-474d-a2de-326594dc97b8" target="_self">Further information on shaft materials

Chemical resistance

All data at room temperature [+20 °C], + resistant 0 conditionally resistant - non-resistant

| Medium | Resistance |

|---|---|

| Alcohols | + up to 0 |

| Greases, oils without additives | + |

| Hydrocarbons | + |

| Fuels | + |

| Strong alkalines | + up to 0 |

| Strong acids | - |

| Diluted alkalines | + |

| Diluted acids | 0 to - |

Moisture absorption

The moisture absorption of iglidur Q290 plain bearings under standard climatic conditions is 3.0% weight. The saturation limit in water is 9.3% weight.

Maximum moisture absorption

at +23°C/50% room humidity.

3.0% weight

Maximum total moisture absorption

9.3% weight

Installation tolerances

iglidur Q290 plain bearings are standard bearings for shafts with h-tolerance (recommended minimum h9). The bearings are designed for press-fit into a housing machined to a h7 tolerance. After installation in a housing with nominal dimensions, the inner diameter of the bearings with E10 tolerance adjusts automatically. For certain dimensions, the tolerance deviates from this depending on the wall thickness (see product range).

Important tolerances according to ISO 3547-1 after press-fit:

| Diameter d1 [mm] | Housing H7 [mm] | iglidur Q290 plain bearing E10 [mm] | Shaft h9 [mm] |

|---|---|---|---|

| up to 3 | +0.000 +0.010 | +0.014 +0.054 | -0.025 +0.000 |

| > 3 up to 6 | +0.000 +0.012 | +0.020 +0.068 | -0.030 +0.000 |

| > 6 up to 10 | +0.000 +0.015 | +0.025 +0.083 | -0.036 +0.000 |

| > 10 up to 18 | +0.000 +0.018 | +0.032 +0.102 | -0.043 +0.000 |

| > 18 up to 30 | +0.000 +0.021 | +0.040 +0.124 | -0.052 +0.000 |

| > 30 up to 50 | +0.000 +0.025 | +0.050 +0.150 | -0.062 +0.000 |

| >50 to 80 | +0.000 +0.030 | +0.060 +0.180 | -0.074 +0.000 |

| >80 to 120 | +0.000 +0.035 | +0.072 +0.212 | -0.087 +0.000 |

| > 120 up to 180 | +0.000 +0.040 | +0.085 +0.245 | -0.100 +0.000 |

Buy iglidur Q290 products in the online shop

- Large selection of moulds and materials

- Available within 24 hours

- No minimum order value

- No minimum order quantity

Typical application areas

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h