Change Language :

igubal - Technical data

application areas

igubal® bearing elements can be used without problems even in harsh environments. In moist or wet environments, the bearings are corrosion-free, and resistant to weak acids and alkalis. The operating temperatures range from -40 to +200°C. The insensitivity to dirt should also be emphasised, because even under extreme soiling, the plain bearings of the igubal® bearing elements do not require a seal. This is true for fine dust as well as coarse dirt.

Temperature limits for igubal® bearing elements

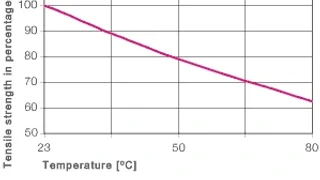

X = temperature [ºC]

Y = percentage tensile strength [%]

Influence of temperature on the maximum tensile strength of igubal®-rod end

| Application temperature in °C | |||

|---|---|---|---|

| Standard | HT version | Food | |

| Minimum | -30 | -40 | -30 |

| Max. long-term | +80 | +200 | +100 |

| Maximum, short-term | +120 | +240 | +110 |

Tolerances

igubal® bearing elements can be used with different tolerances depending on the application. In the standard programme, they are designed with a large bearing clearance, which allows safe operation even at high circumferential speeds. The bore of the inner ring is toleranced to E10. The shafts should be toleranced between h6 and h9. The tolerances can be found in the table. Please contact us if tighter or wider bearing tolerances are required.

Tolerances of the inner diameter of the spherical ball

| Nominal dimension [mm] | Tolerance | |

|---|---|---|

| Plug gauge falls | Plug gauge sticks | |

| 0-3 | x.01 | x.05 |

| > 3 up to 6 | x.02 | x.07 |

| > 6 up to 10 | x.02 | x.08 |

| > 10 up to 18 | x.03 | x.10 |

| > 18 up to 30 | x.04 | x.12 |

| > 30 up to 50 | x.05 | x.15 |

Media resistance

Both the bearing spherical cap made of iglidur® W300 and the housing made of igumid® G are resistant to weak alkalis, weak acids, fuels and all types of lubricants. The moisture absorption of igubal® is around 1.3 % by weight in a normal climate. The saturation limit in water is 6.5%. This must be taken into account with corresponding environmental influences. The HT version can be used for higher chemical resistance.

- + resistant

- 0 conditionally resistant

- - unstable

All data at room temperature [20°C]

Chemical resistance of igubal® bearing elements

| Medium | Resistance | ||

|---|---|---|---|

| Standard | HT version | Food | |

| Alcohols | + up to 0 | + | |

| Hydrocarbons | + | + | + |

| Greases, oils without additives | + | + | + |

| Fuels | + | + | |

| Diluted acids | 0 to - | + up to 0 | 0 to - |

| Strong acids | - | + to - | |

| Diluted alkalines | + | + | + |

| Strong alkalines | 0 | + |

Further advantages

Loads

The load capacity of the maintenance-free igubal® bearing elements is very high at normal ambient temperatures. igubal® bearing elements absorb high forces and weigh only a fifth of conventional metal bearing housings. The excellent damping properties are due to the fact that, unlike steel, the plastic material of the two-part bearing can absorb vibrations.

However, plastic-specific specifications such as temperature dependency and creep behaviour must be taken into account during use. For this reason, the load-bearing capacity of the rod end should be checked on a case-by-case basis in a practical test, particularly in the case of high continuous loads, low load speeds and higher temperatures.

Sliding friction coefficients and speeds

An important advantage of the maintenance-free igubal® bearing elements is that fast rotational movements of the bearing shaft take place directly in the bearing spherical cap made of iglidur® W300. The advantage of this plastic/steel plain bearing is that high speeds are also possible in dry operation. Taking the radial load into account, maximum sliding speeds of up to 0.5 m/s are possible in rotation.

The angular movements of the spherical bearing, on the other hand, take place on the spherical outer diameter of the bearing calotte.

The maintenance-free igubal® bearing elements also allow linear movements of the shaft without further ado.

Thread pitches of the igubal®-rod end

| Thread type | Pitch [mm] |

|---|---|

| M 2 | 0.40 |

| M 3 | 0.50 |

| M 4 | 0.70 |

| M 5 | 0.80 |

| M 6 | 1.00 |

| M 8 | 1.25 |

| M 10 | 1.50 |

| M 10 F | 1.25 |

| M 12 | 1.75 |

| M 12 F | 1.25 |

| M 14 | 2.00 |

| M 16 | 2.00 |

| M 16 F | 1.50 |

| M 18 | 1.50 |

| M 20 | 1.50 |

| M 20 | 2.50 |

| M 22 | 1.50 |

| M 24 | 2.00 |

| M 27 | 2.00 |

| M 30 | 2.00 |

More about igubal spherical plain bearings

Shop

Are you familiar with our products and would like to view the selection in the online shop or order directly?

Tool

In just three steps, you can use the parameters of your application to determine suitable product recommendations, including service life.

Knowledge base

Here you will find the most important information, technologies, questions and answers about igubal spherical plain bearings.

Contact us

Contact details

Alan Hicks07467 956571Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h