Change Language :

Maintenance-free heavy-duty and fibre composite plain bearings

Self-lubricating heavy duty bearings

Composite bearings are a combination of different materials. Mineral materials are woven with fibres, combined with synthetic resins and other additives and then pressed together under high temperatures and pressure.

With our igutex® plain bearings, a robust fibreglass fabric serves as the outer shell, while an inner layer optimised for sliding properties reduces friction on the shaft.

The combination of these materials results in high-strength composite fibre plain bearings that have been developed for very high loads and primarily used in agricultural, construction and mining machinery. As our igutex® composite bearings contain solid lubricants, they do not require any maintenance or additional lubrication.

What is special about igutex fibre composite plain bearings?

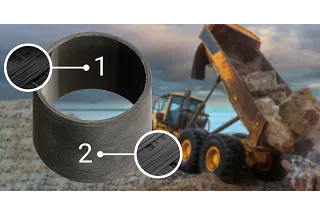

Where injection-moulded plain bearings cannot be used due to excessive mechanical loads, wound igutex® fibre composite plain bearings play to their strength. They consist of two layers:

1 Gliding layer

The gliding layer consists of a filament fabric with solid lubricants, which makes the composite plain bearings self-lubricating and maintenance-free with particularly low coefficients of friction.

2 Base layer

The outer layer of igutex® slide bearings is made of particularly hard-wearing filament fabrics and serves to protect the tribologically optimised inner layer.

Shop igutex® fibre composite bearings

igutex® fibre composite plain bearings are used here

Frequently asked questions

Like all our bearings, igutex® composite bearings require no lubrication as this is already built into the ‘gliding’ layer. igutex® will also accept lubrication, should this be necessary for your application.

Our composite bearings are available as a sleeve bearing with an internal diameter as small as 20mm up to whatever size you need! They can also be manufactured as a thrust washer with gliding surfaces on one or both sides.

Yes, igus® can provide igutex® composite bearings to your required specification, we are also able to provide guidance on machining – just talk to one of our engineers!

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h