Change Language :

igus® lead screws in 3 variations

What exactly is a threaded rod?

A threaded rod is a cylindrical rod with male threads, used for fastening or as a drive system. Common in Europe are metric ISO threads (e.g., DIN 13-1), while other standards include UNC (ANSI/ASME) and trapezoidal threads (DIN 103).

Thread types vary by profile, pitch, turns, and rotation direction. Threaded rods are easy to cut and machine, making them versatile for applications like furniture, mechanical engineering, shelving, railings, and suspended building services. They’re typically anchored in concrete for secure fastening.

Some rods, like trapezoidal or high helix lead screws, serve as motion threads—converting rotation into linear movement. These are more efficient and suited for dynamic loads, often driven by handwheels or motors.

Do you need an individually configured threaded rod? We have the solution.

Steep Threaded Rods

Part of the dryspin® range, steep threaded rods are designed for fast, efficient motion applications. Available in sizes from DS4x2.4 to DS18x100, they’re made from corrosion-resistant stainless steel (AISI 304) or lightweight aluminium.

Manufactured using a rolling process, these rods offer smooth surfaces and cost-effective production—ideal for use with lubrication-free plastic lead screw nuts. Options include right-hand, left-hand, and reverse threads.

Explanation of dryspin® technology

High efficiency and low wear

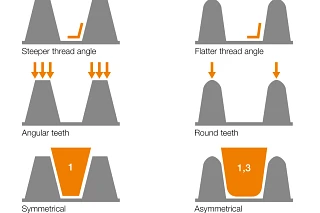

The patented dryspin® steep thread technology was developed by igus® in 2013 and offers numerous advantages over conventional steep threads. Due to the flat flank angle, it efficiently converts the applied force into a translational movement. With the specifications and geometries matched to the plastic nut and lead screw, dryspin® offers even greater service life and efficiency for steep threads. Thanks to the rounded tooth flank geometry, the contact surface between the threaded lead screw and lead screw nut is reduced and the threaded systems run almost silently and vibration-free under load.

The larger distances between the individual dryspin® threads increase the proportion (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and a higher degree of efficiency are decisive for a service life that is up to 5 times longer than that of conventional steep threads.

Threaded rod with trapezoidal thread

In the cross section, the trapezoidal thread corresponds to an isosceles trapezoid with an angle of 15°. The flank angle is 30°. Compared to the standard thread, the trapezoidal thread lead screws has a larger diameter and a larger pitch. The lead angle of single start trapezoidal threaded lead screws is smaller than the arc tangent. This ensures self-locking. Double start lead screws, on the other hand, are not self-locking.

Our trapezoidal threaded rods are available in aluminium EN AW 6082, CF-15 steel (AISI 1015) and stainless steel. The dryspin® trapezoidal threaded lead screws are manufactured rolled as standard and we offer them in right-hand, left-hand and reverse thread directions.

Threaded rod with metric thread

In Europe, the metric ISO thread has become established, also known as the standard thread, normal thread or pointed thread. The outer edges of this thread form converge in a wedge shape. The metric ISO thread is self-locking due to this profile shape. The flank angle between two threads is 60°. Like the thread pitch, the diameter is specified in millimetres and marked with an M (e.g. M8). The thread, which is defined in DIN 13, is used for friction-locked connections. The metric threaded rods are available from us in right-hand thread and stainless steel 1.3041.

- Available in thread sizes M3 to M6

- Available from standard thread to fine thread

- Fine threads are not standard with us, but are of course possible on request

Contact us

Contact details

Robert Day07949 281236Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h