Change Language :

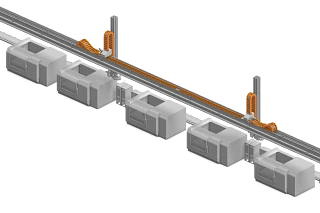

Energy supply systems for the powertrain production line

Long service life, predictable maintenance

The drivetrain production line places high demands on the precision and reliability of the machines. The various stations, some with long distances, form a complex system with high dynamics. Damage to one machine or component has an impact on the entire production line. In the best-case scenario, production runs smoothly and downtimes for maintenance can be planned sensibly.

On average, a motor leaves the assembly line every 14 seconds - at peak times, over 6,000 motors are produced per working day. This output can only be realised with a high degree of automation and reliable components. With smart plastic, our products for predictive maintenance, unplanned failures and system downtimes can be avoided.

Success stories

Our service starts even before installation:

- We plan the optimisation of your system to guarantee maximum service life and increase system availability

- Retrofitting your existing machines as a system partner

- Retrofitting condition monitoring or predictive maintenance to igus® products

- Our energy chains are also available as ready-made systems, e.g. 7-axis, loading gantries

- After installation: regular inspection and maintenance of your energy chain and condition monitoring systems

- At the end of the life cycle, we take the energy chain back and recycle it

Suitable products

Contact us

Contact details

igus® UK01604 677240Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h