Change Language :

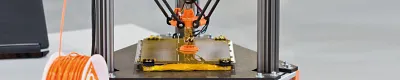

Quick replacement of defective plain bearings: 3D printing service for wear-resistant parts

Camera equipment manufacturer receives a 3D-printed customised component within hours

What do you do when an important replacement part for an exhibit suddenly goes missing on the way to a trade show? The answer of the Berlin-based company Blackcam, a manufacturer of camera movement systems, was to call in our 3D printing service. We use industrial 3D printers to manufacture individual customer components in just a few hours, which are optimised for friction and wear. This is how the missing special lubrication-free plain bearing was made.

Contact us

Contact details

igus® UK01604 677240Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h