Change Language :

Bearing liners for drylin® linear systems

Choosing the most suitable bearing liner for your housing is crucial. igus® has an extensive range of drylin® bearing liners in iglidur® materials which allows all applications to be catered for. Whether for high speed or temperatures from -50°C to +250°C or with FDA/EU conformity.

- Low coefficient of friction

- 100% lubrication-free

- Extremely lightweight

- High chemical resistance

Choose the suitable lined bearings for your linear system

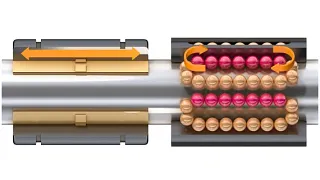

The principle: "sliding instead of rolling"

The advantages of bearing liners compared to recirculating ball bearing system

The iglidur® bearing liners made of high-performance polymer used for drylin® linear systems are completely lubrication and maintenance-free. The principle of the plain bearing leads to further advantages in favour of a drylin® linear system.

Frequently asked questions about drylin® R bearing liners

What are bearing liners?

drylin® bearing liners are polymer liners that fit into drylin® housings and carriages enabling a gliding motion on the shaft or system.

Where can I use bearing liners?

These can be used in any drylin® carriage or housing within the majority of applications. There are various liner materials to cater for varying environments.

Why use igus® drylin® bearing liners?

The liners allow a smooth running operation without the need for lubrication.