Change Language :

Linear axes with lead screw drive

Precision positioning made easy

igus® drylin® linear axes with lead screw drive are designed for precise and maintenance-free positioning tasks across a wide range of applications. Featuring trapezoidal or high helix lead screws, these systems can be operated manually or electrically, achieving travel speeds of up to 1.6m/min depending on load and thread type. With freely selectable stroke lengths—up to 1,500mm for plain-bearing mounted screws and 1,000mm for ball-bearing mounted versions—drylin® axes offer flexible, reliable motion control. Ideal for automation, laboratory equipment, and industrial machinery, they combine durability with smooth, lubrication-free performance.

Leadscrew linear axis options

Configure your custom linear system online

Advantages of lead screw axes

When a cost-effective, ready-to-install solution is desired, lead screw axes are often the first choice. You can see here what other advantages the linear drive has over other systems with the aid of a lead screw:

Precise positioning

By directly converting the rotating motion from the lead screw to linear motion, very accurate and repeatable positioning is achieved, which is critical in tight tolerance and high precision applications.

Compact design

Lead screw axes are also available in particularly small versions. Their compact design makes them perfect for all applications where only a small amount of installation space is available. Also discover our complete miniature series.

High load capacity

Lead screw drives in linear modules are able to carry and move very high loads. In contrast to flexible toothed belts, for example, lead screw axes can ensure efficient force transmission thanks to their low rigidity.

Low-friction movement

Linear modules with lead screw drives are exceptionally low-friction. The constant, precise movement of the lead screw drive minimises friction and thus also wear on the components. This ensures a longer service life for the entire lead screw axis.

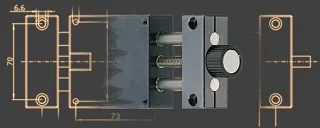

Structure of a lead screw axis

A lead screw axis contains several complex components that must fit together perfectly. A precise structure plays a key role in the performance and accuracy of the linear axis. Here you can see the most important components at a glance.

Different materials within the axis

Application examples with lead screw axes

Free sample & white paper

Contact us

Contact details

Adam Sanjurgo07977 018171Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h