Change Language :

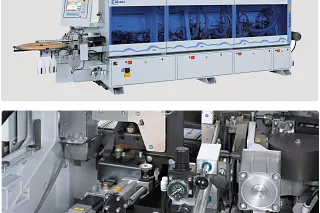

Lead screw nut application in edge banding machine

Technical data:

► What was needed: Lifelong zero clearance of the adjustment unit and thus precise glue application without maintenance

► Requirements: No sticking due to the fine wood dust, high precision, absolute freedom from lubrication and maintenance, flexibility in production

► Products used: Anti-backlash trapezoidal lead screw nut, stainless steel trapezoidal threaded spindle

► Success for the customer: Brandt was so impressed by the clearance and maintenance-free nature of the newly developed adjustment system that it is considering converting all of the spindles in the machines to the maintenance-free anti-backlash system. "This will allow us to further increase the reliability of the machines," says Ralf Garnjost confidently. Various tribo-optimised polymer bearings in special shapes are also proving their worth in the edge banding machines. "The absence of lubricants pays off in all areas. lubrication and dust don't mix at any point."

Lubrication and clearance-free dryspin® screw drives ensure precise glue application

What happens when fine and ultra-fine wood dust meets lubricant? Adhesions are inevitable. The functionality of woodworking machines can be permanently impaired. In its new development of a glue application system for edge banding machines, a medium-sized company therefore relies on lubricant- and maintenance-free screw drives with anti-backlash-lead screw nut, which ensure zero clearance of the adjustment unit and thus precise glue application for the life of the machine.

Founded in 1955, the company's product programme is geared towards all trends in customer requirements and machining tasks. The focus of machine development is on practical and economical solutions that guarantee customers worldwide the best possible production results. Production is carried out by around 280 employees in Lemgo, with additional sites in the Czech Republic, Poland and China. With an export share of around 80 per cent and customers in over 90 countries, the edgeband specialist is one of the world's leading suppliers.

Glue application with precision

One of the latest developments is the QA 45 adhesive application system, which is available as an option from a certain machine size. It is characterised, among other things, by short heat-up times and quick changeover options and therefore a high degree of flexibility when processing a wide variety of adhesives, edgebands and panel materials. "With this system, we want to make it possible to automate adhesive application. This allows us to offer our customers greater ease of use. Adhesive application is otherwise done more or less by eye," says Ralf Garnjost, describing the initial situation. "Our aim was to create an inexpensive yet sophisticated solution that would prove its worth in day-to-day operations."

In addition to the automatic cleaning function, the innovations of the new glue application system include a clearance-free adjustment, which was realised in cooperation with the company igus® GmbH, Cologne. The centrepiece of this adjustment is the anti-backlash-lead screw nut, which was presented as a standard product at Hannover Messe Industrie 2010. "Backlash" refers to the backlash caused by the axial play in a screw drive.

The anti-backlash-lead screw nut offers many advantages:

► Reduction of backlash over the entire service life

► Permissible wear is guaranteed

Non-lubricated and extremely dirt-sensitive screw drive

► No adhesion of dirt and dust to lubricants

Anti-backlash spindle nuts for metric threads have been used in the glue application system for several months as a special development: lubrication-free, vibration- and noise-damping, they ensure maximum precision.

Precise travel

"Due to the difficult environmental conditions in woodworking, all other conventional solutions tend to become susceptible to maintenance in everyday operation," explains Thorben Fritz, mechanical engineer in the design department, who was largely responsible for the development of the adjustment unit. "However, thanks to our many years of experience with tribo-optimised plain bearings from igus® in our machines, we were convinced right from the start that we could guarantee precise format adjustment in the long term with lubrication-free machine elements." In the area of spindle systems - up to ten axis units cover a wide variety of tasks in an edgebander - the edgebanding specialist has so far relied on brass nuts, which are not clearance-free. Due to the existing backlash, the desired position is not always achieved and repeatability is poor.

The adhesive application on the edges is metered with the aid of the adjustment. If the travel is not exact, deviations of several tenths occur, which results in a reduction in the quality of the adhesive application. For this reason, clearance-free adjustment was particularly important in the development of the application system. Classic solutions such as lead screw nuts braced against each other were quickly discarded. "These are a variety of design approaches that are not only very complex, but also require a relatively high drive torque from the actuator," explains Ralf Garnjost. "In contrast, we try to drive our axis systems with a relatively low torque." The low coefficient of friction of the new spindle-lead screw nut system ensures the low drive torque required.

General conversion to maintenance-free linear systems and plain bearing solutions

Contact us

Contact details

igus® UK01604 677240Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h