Change Language :

Wear-resistant plastic gear racks

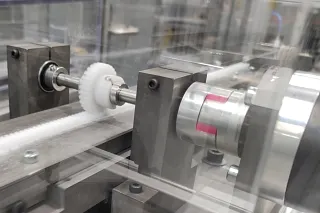

A gear rack is an elongated component with a series of teeth. It is used to transmit force between one or two gears in order to make a rotational movement linear.

When combining gear rack and gear, it is important to ensure that they use the same module to create the best movement.

igus® has three production processes for gear racks:

- Injection moulding with iglidur® high-performance polymers

- Mechanical CNC processing from iglidur® bar stock

- 3D printing with iglidur® laser sintering or FDM materials

This enables us have a gear combination for every application.

Overview of gear rack materials

Are you looking for CAD data?

In our CAD database, you can view our gear rack CAD data or download it, in both 2D and 3D format

This service is free of charge and there is no need registration required.

Your questions and our answers (FAQ)

Where is a rack and pinion gear used?

Rack and pinion gear is used where you are looking to convert the rotational movement of the pinion gear into a linear motion.

What is a rack and pinion gear system?

A rack is usually a square or round section of material which has straight teeth cut into it. The pinion gear is cylindrical gear who's teeth match with racking which enable them to mesh together. When they are working together they are known as a "rack and pinion system".

How to design a rack and pinion gear?

When designing a rack and pinion gear you need to ensure the they have matching modules. The module of the rack and the pinion gear dictates the size of the teeth, so to enable the rack and pinion gear to mesh together the size of the teeth must match.

Contact us

Contact details

Alan Hicks07467 956571Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h