Change Language :

iglidur® N54 - Material data

Material table

General specification

Unit

iglidur® N54

Test method

density

g/cm³

1,13

Colour

green colour

max. Moisture absorption at 23°C/50% room humidity.

% by weight

1,6

DIN 53495

max. total moisture absorption

wt.-%

3,6

Sliding friction coefficient, dynamic, against steel

μ

0,15-0,23

pv value, max. (dry)

MPa x m/s

0,5

Mechanical specification

flexural modulus

MPa

1.800

DIN 53457

flexural strength at 20°C

MPa

70

DIN 53452

Compressive strength

MPa

30

maximum recommended surface pressure (20°C)

MPa

36

Shore D hardness

74

DIN 53505

Physical and thermal specification

Upper long-term application temperature

°C

+80

Upper short-term application temperature

°C

+120

Upper short-term ambient temperature1)

°C

+140

Lower application temperature

°C

-40

thermal conductivity

W/m x K

0,24

ASTM C 177

coefficient of thermal expansion (at 23°C)

K-1 x 10-5

9

DIN 53752

Electrical specification

Volume resistivity

Ωcm

< 1013

DIN IEC 93

surface resistance

Ω

< 1011

DIN 53482

- Without additional load; no sliding movement; relaxation not excluded

Table 01: Material data

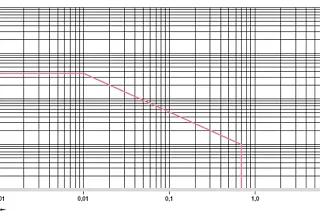

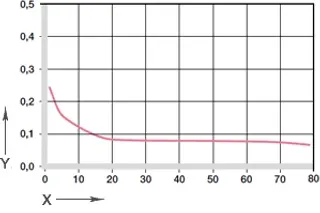

diagram. 01: Permissible pv value for iglidur® N54 plain bearings with 1 mm wall thickness in dry operation against a steel shaft, at +20 °C, installed in a steel housing

X = surface speed [m/s]

Y = load [MPa]

iglidur® N54 is the first iglidur®material that is largely based on biopolymers. In addition to the fact that all iglidur®materials are already lubricant-free, this is a further step towards a positive environmental balance. Good coefficients of friction coupled with service lives that allow series use in sporadically moving applications give this material a firm place in the iglidur®programme.

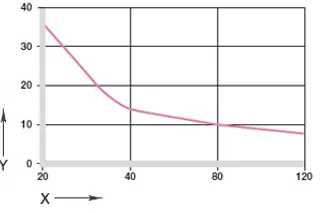

diagram. 02: maximum recommended surface pressure as a function of temperature (36 MPa at +20 °C)

X = temperature [°C]

Y = load [MPa]

Mechanical specification

The maximum recommended surface pressure is a mechanical material parameter. It cannot be used to draw conclusions about the tribology. The compressive strength of iglidur® N54 plain bearings decreases with increasing temperatures. diagram.02 illustrates this relationship. At the long-term permissible application temperature of +120 °C, the permissible surface pressure is still just under 10 MPa.

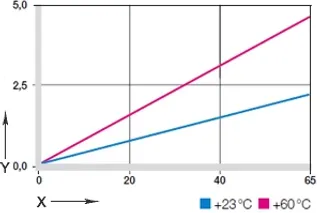

Diagram 03: Deformation under pressure and temperature

X = load [MPa]

Y = Deformation [%]

diagram. 03 shows the elastic deformation of iglidur® N54 under radial load.

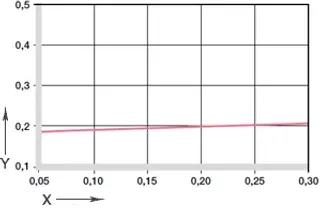

Diagram 04: Coefficient of friction as a function of the surface speed, p = 1MPa

X = surface speed [m/s]

Y = coefficient of friction μ

Friction and wear

The coefficient of friction of iglidur® N54 is low. However, it must be noted that an excessively rough sliding partner increases the friction. We recommend a shaft roughness (Ra) of 0.1 to a maximum of 0.4 μm.

The coefficient of friction of the iglidur® N54 bearing is only slightly dependent on the sliding speed.

The influence of the load is greater, with the increase of which the coefficient of friction drops to 0.8.

Diagram 05: Coefficient of friction as a function of the pressure, v = 0.01m/s

X = load [MPa]

Y = coefficient of friction μ

iglidur® N54

dry

Grease

oil

water

coefficient of friction µ

0,15 - 0,23

0,09

0,04

0,04

Table 04: coefficient of friction for iglidur® N54 against steel

(Ra = 1 µm, 50 HRC)

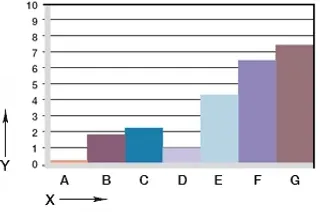

diagram. 06: Wear, rotating application with different shaft materials, p = 1 MPa, v = 0.3 m/s

X = Shaft material

Y = wear [μm/km]

A = aluminium, hard anodised

B = free cutting steel

C = Cf53

D = Cf53, hard chrome-plated

E = HR carbon steel

F = 304 SS

G = high grade steel

Shaft materials

It is important to select the suitable shaft material. it cannot be said in general that iglidur®® N54 is better suited for hard or soft shafts, but "hard" shaft surfaces tend to lead to better service lives. At loads from 1 MPa, the wear increases noticeably and continuously.

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h