Change Language :

Stainless steel lead screws

Corrosion and chemical resistant

Stainless steel lead screws are the standard material for our lead screws. In combination with our drylin lead screw nuts, there is 100% freedom from corrosion. Tests show that wear is reduced by up to 25%. And we can also find a suitable material for your application in extreme environmental conditions. Our experts offer the solution for your specific application.

With specifications and shapes matching the polymer nut and lead screw, dryspin provides up to 30% longer service life and efficiency for high helix threads. Due to the rounded tooth geometry, the contact area between lead screw and nut is reduced, and the lead systems operate quietly and without vibration under load.

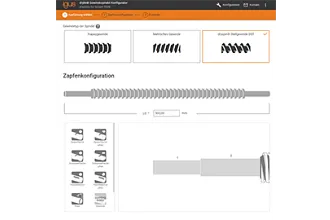

Lead screw options

Configure customer-specific designs in lead screw technology online

Lead screw drive expert

► Assistance in selecting the optimum lead screw drive

► Service life calculation for the desired configuration

► PDF download with all details for the desired application

► Display of price and delivery time for your individual configuration

Lead screw configurator

► Individual pin machining without CAD software

► 2D dimensioned drawing and 3D step file, generated directly online

► Immediate price calculation

► Order online or request quotation

► Individually configurable reverse lead screw

Stainless steel lead screws customer application examples

Our manufacturing methods for drylin® stainless steel lead screws

Thread rolling - our standard

A workpiece is placed centrally between two tools with profile. They rotate simultaneously, the thread is rolled into the surface of the raw material by cold forming. The thread profile is transferred to the workpiece by stress and rotation. The thread is ready.

More about thread rolling

Thread whirling - for special sizes

Thread whirling for special sizes requires only one tool. It is ring-shaped and is clamped around the appropriate workpiece. This rotates very slowly, while the whirling tool rotates outside at very high speed. The thread is produced by inward facing cutting bits.

More about thread whirlingContact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h