Change Language :

Drive technology application examples

Applications of linear drives

Linear axes with lead screw drive, toothed belt and rack axes as well as linear units in various material and shaft combinations: drylin® drive technology from igus® is already being used successfully in a wide range of industries and ensures less machine downtime without the use of external lubricants.

Where conventional drive systems fail, igus® ensures absolute operational reliability with its large product portfolio.

Would you like more information about drylin® SHT drives or do you need an individual consultation? Our experts will be happy to get in touch with you.

drylin® drive technology by industry

The drylin drive technology from igus® is already being used successfully in a wide variety of industries and ensures fewer machine downtimes without the use of external lubricants. In areas where conventional drive systems reach their limits, igus® ensures greater operational safety with its drylin® E product portfolio.

On this page you will discover numerous practical applications in which our linear units with lead screw, toothed belt and rack and pinion drives, as well as our electric motors, were used. From individual motor applications to complete drive systems: we always find the best solution for your individual application.

Latest applications & highlights

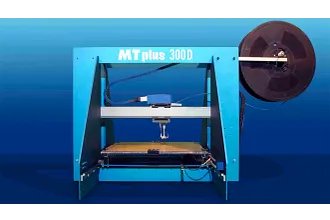

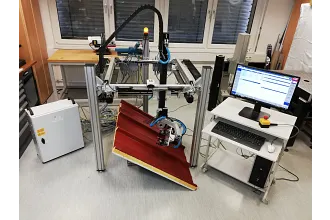

3D printer

3D concrete printer for building structures

Thanks to the lack of lubricants, the igus® toothed belt axes offer a solution that also works reliably in dusty environments.

XXL 3D printer for house facades

This 3D printer was used to build the façade of the "Europe Building" in Amsterdam. Our drylin multi-axis linear robots guide the print head.

Linear bearings in 3D printers

A finished and completely lubrication-free complete solution consisting of cable guide, linear technology and drive was installed in this 3D printer from EVO tech GmbH.

3D printer to replicate

This printer produces three-dimensional plastic parts in a timely manner. Modular systems such as drylin bearings enable easy installation by the end customer.

Cleanroom 3D printer

Precise, reliable cleanroom 3D printer for processing thermoplastics. Numerous drylin® products work together here.

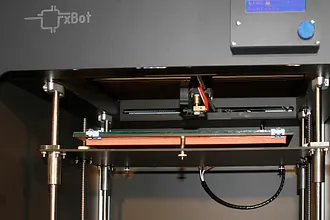

3D plastic parts printer

The xBot is a 3D printer that can produce essential parts of itself. It prints precisely and quickly using the Fused Deposition Modeling (FDM) principle.

Automotive industry

Rotating car wash brush system

Noyen, a Polish manufacturer, produces a rotating car wash brush system for washing complex parts automatically after they are painted.

Construction machinery industry

Linear axis for bend testing device

No lubrication or maintenance: A lead screw linear system and a linear rail are used in durable Munsch weld seam testing tools.

Field drainage machine

An innovative field drainage machine that can manoeuvre plastic drainage tiles on the job site and unroll plastic tiles alongside the trenching and ploughing equipment.

Beverage industry

Maintenance-free filling plants

In the filling systems, a lead screw module ensures easy positioning of the 80kg filling head above the container.

Automated cocktail mixer

A linear axis moves the glass in this cocktail mixer reliably and maintenance-free. It is perfectly suited for hygiene-sensitive tasks.

Innovative packing aid gripper

drylin linear bearings in this packing aid gripper operate failure-free with dirt and impacts.

Vending machine for cleaning reusable cups

An automatic cleaning machine that disinfects cups in just a few seconds with steam at 140°C.

Automatic beer dispenser

An automated beer dispensing system for festivals and large events. Draw beer in just a few seconds.

Adjustment system in espresso machine

Robust components are required that work even under high temperatures and possible contamination.

Food industry

Suction pad insertion machine

Low Cost Automation ensures precise format adjustments in packaging technology.

Linear bearings, plain bearings and drive elements in thermoform packaging system

Lubrication-free linear technology and polymer slewing ring bearings are used in sterilisation machines.

Aerospace engineering

3D printing for space debris removal

This system is a new ejection mechanism for space travel.

Rocket module for space debris removal

A rocket module that collects space debris from orbit.

Mechanical engineering

Maintenance-free filling plants

Positioning with maintenance-free lead screw modules

Linear systems in diaper production plants

Products from the modular linear bearing system range provide the necessary flexibility when changing between different formats.

Film packaging machine

Automated format changes and positioning tasks are accomplished in the modular Veprotec packaging machines with igus linear bearing technology.

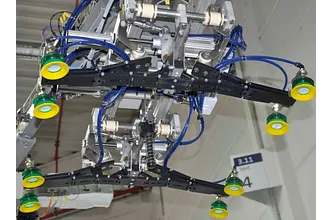

Innovative packing aid gripper

drylin linear bearings in this packing aid gripper operate failure-free with dirt and impacts.

Suction pad insertion machine

Low Cost Automation ensures precise format adjustments in packaging technology

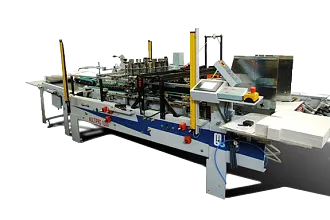

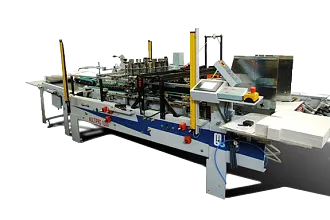

Filling height adjustment in folding and gluing machines

When designing folding box gluers, Bernhardt Maschinenbau relies on lubrication-free and maintenance-free linear plain bearings.

Linear bearings, plain bearings and drive elements in thermoform packaging system

Lubrication-free linear technology and polymer slewing ring bearings are used in sterilisation machines.

Production machines

A manufacturer of production machines for brushes is an example of the application areas and properties of iglidur and drylin bearing products.

Material handling

Linear movements in industrial vehicles

Ready-to-install drylin linear axes allow for trouble-free distance adjustments on Jungheinrich forklifts - from the steering wheel to the fork.

Automatic order picking by robots in logistics

The automation expert Magazino relies on our linear axes, plain bearings and e-chains in its pick-by-robot system.

Product pusher with 16m long energy chain

An autoglide energy chain supplies a transport system with electricity. It works without a guide trough and without blocking the industrial vehicles.

Medical technology

Linear axis in the laboratory for DNA diagnostics

drylin linear bearings in medical devices: precise pressing of electrophoretic glass plates in a DNA pointer system

Conveyor track in medical technology

This medical technology application combines a conveyor belt with high-resolution cameras to monitor products.

Optical industry

Format adjustment in inspection systems

In Gefra's optical testing systems, modular drylin linear axes with actuators ensure the automated adjustment of the lighting units.

Linear axis for e-scooter lift

The "idea train" presents new concepts for tomorrow's passenger transport, including an e-scooter lift that works with maintenance-free drylin linear axes.

TV lift

A maintenance-free, shock-resistant and durable, motorised TV lift. This is used in caravan construction.

Testing technology & quality assurance

Visual inspection of small components

For the electrical adjustment of the lighting units, Gefra uses complete linear drive units from the drylin® product range.

Filling plant in bioanalytics

Lubrication-free and maintenance-free drylin linear axes with motor enable optimal use of installation space for handling liquids in the M2-Automation filling system.

Road core drill

The road core drilling device for taking samples from roads and airport runways requires products that are particularly robust and also light and maintenance-free.

Linear axis for e-scooter lift

The "idea train" presents new concepts for tomorrow's passenger transport, including an e-scooter lift that works with maintenance-free drylin linear axes.

Laser station for marking industrial products

A laser station for marking industrial products.

Mobile scanning machine

A mobile scanning machine that can be used to inspect even complex plates and free forms with air ultrasound.

2in1 - testing booth and conference table

A testing booth that transforms into a meeting table in just a few seconds.

Straightening technology

Fast, straight, precise: This is how the requirements in sheet metal processing can be summarised. Sophisticated straightening technology makes all this possible.

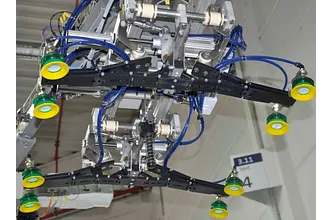

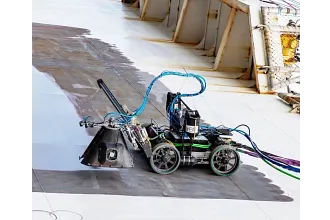

Offshore robots for cleaning & repairs

Remotion's robots work both below and above the waterline and carry out dangerous operations.

Autonomous inspection boat

For an autonomous inspection boat, components are needed that are inflatable and maintenance-free. Furthermore, the products must withstand the harsh conditions in the port.

High pressure water chamber

For testing in the high-pressure water chamber, products that are lubrication-free and can withstand high amounts of splash water are needed.

Packaging

Filling height adjustment in folding and gluing machines

When designing folding box gluers, Bernhardt Maschinenbau relies on lubrication-free and maintenance-free linear plain bearings.

Linear systems in diaper production plants

Products of the modular linear bearing system range provide the necessary flexibility when changing between different formats.

Suction pad insertion machine

Low Cost Automation ensures precise format adjustments in packaging technology.

Linear bearings, plain bearings and drive elements in thermoform packaging system

Lubrication-free linear technology and polymer slewing ring bearings are used in sterilisation machines.

Film packaging machine

Automated format changes and positioning tasks are implemented in the Veprotec packaging machines with linear bearings.

Innovative packing aid gripper

drylin linear bearings in this packing aid gripper operate failure-free with dirt and impacts.

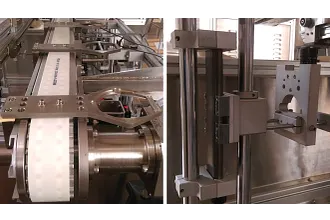

Bearing technology for labelling machines

Label up to 50,000 containers per hour with just one unit.

Science and research

Room linear robot for filling plant in bioanalytics

Lubrication-free and maintenance-free linear axes with motors enable optimal use of installation space for handling liquids in filling systems.

Computer tomograph on drilling platform

diondo has built a cost-effective CT for seabed exploration using drylin motor components.

Special measurement setup with lead screw axis, motor & control system

From concept to implementation. Development of an R&D measurement setup for quantifying wafer specifications.

Contact us

Contact details

Lee Wilkins07736 269217Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h