Change Language :

E4/4 system

The E4.1 predecessor for long travels and side-mounted applications

The E4/4 system is used in two areas: For extremely long travel distances and for unsupported applications lying on their side. The famous "rear grip" between two chain links makes this possible. Compressive forces and rigidity are increased, which increases resistance to wet and harsh weather conditions. Special roller chain links make E4/4 a true specialist for long travel distances. The undercut design - the simple attachment in the grooves provided - also enables the outstanding ESD performance. The chain links are always close together, as current can flow when they come into contact with each other (please note: this only applies to the special conductive material igumid® ESD and does not apply to the standard series in this catalogue).

Full-width, can be opened on both sides - For particularly demanding applications

Series 2828

inner height hi: 32 mm

inner width Bi: 50 - 400 mm

bend radius R: 63 - 300 mm

pitch: 56 mm

Series 3838

inner height hi: 42 mm

inner width Bi: 50 - 400 mm

bend radius R: 75 - 350 mm

pitch: 67 mm

Series 4040

inner height hi: 56 mm

inner width Bi: 50 - 600 mm

bend radius R: 135 - 500 mm

pitch: 91 mm

Series 5050

inner height hi: 80 mm

inner width Bi: 50 - 600 mm

bend radius R: 150 - 1000 mm

pitch: 91 mm

Semi-rigid, can be opened on both sides - For almost all applications

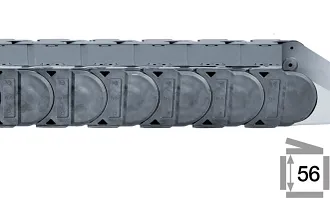

Series 2928

inner height hi: 32 mm

inner width Bi: 50 - 400 mm

bend radius R: 63 - 300 mm

pitch: 56 mm

Series 3938

inner height hi: 42 mm

inner width Bi: 50 - 400 mm

bend radius R: 75 - 350 mm

pitch: 67 mm

Series 4140

inner height hi: 56 mm

inner width Bi: 50 - 600 mm

bend radius R: 135 - 500 mm

pitch: 91 mm

Series 5150

inner height hi: 80 mm

inner width Bi: 50 - 600 mm

bend radius R: 150 - 1000 mm

pitch: 91 mm

"Heavy duty", full-width, can be opened on both sides - extra robust! Standard for long travel distances!

Series 4040HD

inner height hi: 56 mm

inner width Bi: 50 - 600 mm

bend radius R: 135 - 400 mm

pitch: 91 mm

Series 5050HD

inner height hi: 80 mm

inner width Bi: 50 - 600 mm

bend radius R: 150 - 500 mm

pitch: 91 mm

Series 8840HD

inner height hi: 56 mm

inner width Bi: 75 - 462 mm

bend radius R: 135 - 400 mm

pitch: 91 mm

Series 9850HD

inner height hi: 80 mm

inner width Bi: 75 - 462 mm

bend radius R: 150 - 500 mm

pitch: 91 mm

e-tube, can be opened on both sides - Fully closed, excellent cable protection

Series R7728

inner height hi: 32 mm

inner width Bi: 50 - 300 mm

bend radius R: 100 - 300 mm

pitch: 56 mm

Series R7838

inner height hi: 42 mm

inner width Bi: 50 - 300 mm

bend radius R: 125 - 350 mm

pitch: 67 mm

Series R8840

inner height hi: 56 mm

inner width Bi: 75 - 462 mm

bend radius R: 150 - 500 mm

pitch: 91 mm

Series R9850

inner height hi: 80 mm

inner width Bi: 75 - 462 mm

bend radius R: 200 - 1000 mm

pitch: 91 mm

Real-world examples

Bucket wheel excavator

India, in the state of Punjab, in the village of Banawala: a huge bucket-wheel excavator stands here, extracting the delivered piles of coal and transporting them via conveyor belt towards the boiler. It moves along a rail system over a distance of 700 metres. And the power cables follow it - inserted in a heavy-duty roller chain from the 5050RHD series from igus® (5050RHD.30.300.S10.0) and thus protected from flying coal.

Contact us

Contact details

Justin Leonard01604 677240Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h