Change Language :

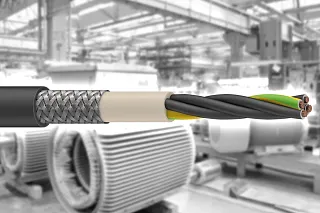

Motor cables for movement in energy chains

What is a motor cable?

A motor cable supplies energy to a motor. The cables contains cores – three black cores for Phases L1, L2, and L3 and a green/yellow core for the earth core.

Today, coil windings in the motor are usually interconnected to form a star or triangle. This is how the number of cores is limited to four. A cable with or without shielding can be selected, depending on cable requirements with respect to interference or environment sensitivity. And, of course, the cable is manufactured with a variety of jacket qualities and mechanical classes

Would you like more information about chainflex® cables or do you need an individual consultation? Our experts will be happy to get in touch with you.

50% off surplus cable stock

In our online shop, discover surplus cable lengths at a 50% discounted rate!

These set lengths from the standard range maintain the same quality as the rest of our chainflex® cables and are backed by a 4-year guarantee.

Simply visit your desired cable within our shop and check for surplus lengths available at half price.

Shop chainflex® motor cable types

Multi-core vs. single core

It is now possible to design cables with single cores, especially for large drives. This solution offers several advantages over classical four-core versions. Probably the biggest is the much lower price that can be offered due to a different, more cost-effective manufacturing process. The single-core solution is also more robust and thus suitable to the small installation space available in energy chains and still delivers a longer service life. This is particularly noticeable on long travels. Connection to the motor is easier with thinner single-core cables, but they need special mounting. We have lots of experience with this sort of challenge, so we always have the products necessary for a solution in stock.

Advantage of TPE for abrasion, cold and service life

The majority of our motor cables have the high-end material TPE as the outer sheath material. This material is particularly suitable for applications in extreme temperature ranges. This is because the temperature range for TPE motor cables is defined in energy chain as -35°C to +90°C. This means that applications in deep-freeze areas or applications in very warm environments are just right for this material. In addition, TPE has another special feature - maximum abrasion resistance. In direct comparison to PVC & PUR, TPE has better abrasion behaviour and is therefore ideal for high-end applications for the highest service life.

Haven't found the right cable yet?

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h