Change Language :

3D printing service

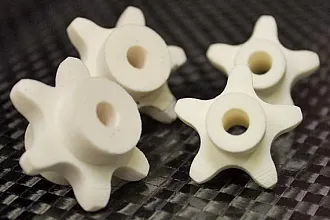

Wear-resistant custom 3D printed parts

Within 3D printing, components are designed as digital 3D models and then additively manufactured layer by layer. The 3D printing service from igus® supplies components made from our own wear-resistant plastic with no minimum order quantity. We offer solutions specifically for applications where conventional materials quickly reach their limits - our plastics have up to 50 times higher wear resistance than regular 3D printing plastics. You simply upload the CAD model of your custom component online and receive it printed in the desired quantity.

Don't have a CAD model to hand?

With our CAD configurator, you can easily create a 3D model for different types. We also offer you planning security with our service life calculator, which can calculate the expected service life of each individual component online.

3 steps to your 3D printed parts

Who is our 3D printing service suitable for?

Industrial 3D printing offers the ideal solution for many crucial problems. Find out more here about the typical challenges that the 3D printing service from igus® overcomes. Does your application have special requirements? Then you are welcome to discuss the solution directly with an igus® expert.

Component broken and a spare part is difficult to obtain?

A spare part can save the machine! Find out how Conti Tech hose GmbH was able to cost-effectively replace a defective cross-threaded lead screw using our industrial 3D printing service.

Do you need to deliver individual components or small batches quickly?

A small missing component can cost a lot of money. With 3D-printed linear actuators, which were delivered in a very short time, thyssenkrupp has prevented this. Find out more here!

Does the application require lightweight construction or lubrication-free components?

A metal gearbox may be too heavy for the desired movement. It also requires additional lubrication, which is not permitted in some environments. Cor.Sync solved both problems with us! How?

Special geometry of the component only realisable at high cost?

Once the perfect design for a component has been found, it must not fail due to the manufacturing process. Discover how the Zurich University of Applied Sciences realised its creative project with industrial 3D printing!

Options for post-processing and finishing

Components manufactured using the SLS process can be subsequently smoothed, coloured or mechanically reworked for an additional charge. Mechanical reworking can include, for example, the insertion of threads or thread inserts as well as the production of components with tight tolerances.

Upload CAD model and receive prices immediately!

More about the CAD configurators

Free of charge 3D printed sample options

Select a sample part and test tribologically optimised 3D printing materials

Convince yourself of the quality and advantages of our materials for industrial 3D printing: Are you interested in 3D printed components, but would like to test them before making a final decision? Then you can order a free sample part from us.

Industrial 3D printing in practice

3D printing process in use

Discover the areas of application in which the igus® 3D printing service has played a decisive role.

Go to the applications

Design guide for printing

Get practical tips on designing functional parts for production in the 3D printing service.

Download the design guideContact us

Contact details

Alan Hicks07467 956571Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h