Change Language :

What does soldering mean?

Frequently asked questions

▲ Tech up

What are the available soldering methods?

Soldering processes are categorised (according to DIN 8505) according to various aspects. A distinction is made between soft soldering and hard soldering: Soft soldering involves soldering with solders whose liquidus temperature is below 450 °C. Hard soldering, on the other hand, involves soldering with solders whose liquidus temperature is between 450 and 900 °C. Brazing, on the other hand, involves soldering with solders whose liquidus temperature is between 450 and 900 °C. Brazed joints are usually mechanically more stable than soft-soldered joints.

Why manual solder connections are good, but technically supported ones are better

This increases quality and safety, even with manual work

Both crimped and soldered connections are suitable for making electrical connections. The latter are usually favoured when electrical conductivity needs to be constantly ensured over a long period of time or when the connection point needs to be permanently sealed.

But be careful: soldering needs to be skilful. What often appears simple at first glance is, on closer inspection, a complicated process that needs to be mastered. The white paper presents the most serious errors in the production of soldered joints. Using the example of the harnessing of cable and cable carrier systems, it explains why technology-supported soldered joints are preferable to those made by hand in an industrial environment.

The paper also discusses the economic advantages resulting from the reproducibility of soldering results. It concludes with the risks that manual soldering entails for people and materials and how these can be minimised.

What are the advantages of machine-supported soldering?

Professional soldering station at igus readychain

Mechanical engineers and system integrators who cannot rely exclusively on crimp connections must pay more attention to the quality of the soldered connections. This is the only way to ensure that the electrical conductivity of components remains constant over a long period of time and that the connection point is permanently protected, e.g. from the influence of gases or liquids.

There are also other advantages of machine-supported soldering:

- Reproducible quality

- Increased safety in the workplace thanks to integrated extraction systems

Quality prevails!

readychain® Application examples from practice

▼ Reduce costs

Advantages of industrial harnessing

No. 1 worldwide for chain-compatible drive cables

The igus® readycable® range extends from a large selection of cables in accordance with various manufacturer standards, such as Siemens, SEW or Beckhoff, to cables for video/vision technology and prefabricated Ethernet cables up to CAT7. You can realise the following cost benefits with each individual cable:

- Ready to connect directly from the cable manufacturer

- Up to 7 price classes with the same electrical specification

- In desired length: accurate to the centimetre

- No minimum order value, no minimum order quantity

- Ready for dispatch in 24 - 48 hours

- Customised assembly is part of our daily business

Why our products keep delivering what they promise

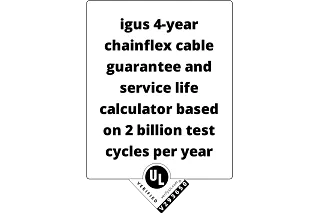

UL verified: igus® receives the highest recognition from a globally respected testing organisation

We give a 4-year guarantee on our cables with a clear conscience, because with over 30 years of experience in our 3,800 m² test laboratory and 700 parallel tests, we can make reliable predictions about the service life of our cables and the ready-to-connect preassembled end systems.

We are now the first German company to have this promise validated for our cables. In a complex certification process, the US institute "Underwriters Laboratories" confirmed the accuracy of the statement "igus® 4-year chainflex® cable guarantee and service life calculator based on 2 billion test cycles per year". This makes us, as a Cologne-based company, the first in Europe to have the truthfulness of an advertising statement confirmed by a testing institution. In future, no chainflex® cable will leave the factory anywhere in the world that is not labelled with the UL marketing label with its unique number B129699, which refers to igus®.

These statements on igus® quality create reliability and planning security for your entire investment process; even more so now that they have been confirmed by an external body! You can read all about UL verified and the associated certification process here free of charge:

Tech up, Cost down

We will show you solutions that can save you up to 88% assembly time, reduce weight by up to 48% or cut storage costs to zero.

Determine your individual savings potential and the optimum solution when it comes to tech up and saving costs.

Click here for the products:

Industrial connectors

Power connectors, signal connectors and several thousand connector components - this is how igus® creates high material availability with short delivery times.

Cable sold by the metre

Cables sold by the metre for moving applications in the energy chain: chainflex® meets all requirements for electromagnetic compatibility safety as well as standards and guidelines such as UL, CSA, EAC and many more.

Ready-to-connect drive cables

With around 4,600 pre-assembled motor, servo, signalling and encoder cables, igus® is the world's No. 1 for pre-assembled cables for use in energy chains.

Ready-to-install cable carrier systems

Ready-made cable carrier systems from a single source: save up to 80% on process costs with our igus® readychain® offers.

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h