Change Language :

Reduce maintenance costs with predictive maintenance

i.Cee predictive maintenance in automotive industry

In automotive production, the conveyor belt never stops. Collaborating robot arms for assembly and welding work are in continuous use, as are all the components that supply them with energy and data. It is precisely in such environments that intelligent concepts in the style of predictive maintenance make the most sense. Whether a new project for Industry 4.0 or efficiency-driven retrofitting - our smart plastics solutions are available as universal modular systems and can be individually adapted to any system.

Would you like more information about our smart plastics? Our experts will be happy to get in touch with you.

How does predictive maintenance work at igus®?

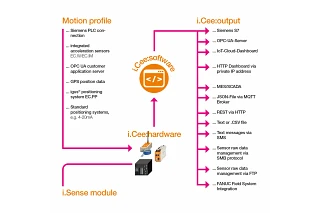

Smart networking of individual components creates the solid foundation for predictive maintenance concepts. At igus®, predictive maintenance is summarised under the term i.Cee.

The central element of this system is the i.Cee software. Sensors on the energy chain, the plain bearing bush, or a linear carriage, transform products deliverable from stock into smart products.

This upgrade creates the capability of determining your igus® product's maximum service life and the i.Cee system also tells you the perfect time for servicing it.

Algorithms adapt the service life and the service time to the equipment's use. The software we provide, a few sensors and the new communication module i.Cee plus II transform standard products available from stock into smart energy supply or bearing technology quickly and easily.

What are the differences between condition monitoring and predictive maintenance?

Different production areas ...

... smartly connected

You determine the manner of data transfer and access

Data transfer within your local corporate network (i.Cee:local) or on a secure cloud (i.Cee:cloud)

Various applications using Smart plastics

Frequently asked questions

What are igus® smart plastics? What is Industry 4.0?

Read more of our frequently asked questions about predictive maintenance.