Change Language :

Intelligent breakage detection for e-chains

Unfortunate circumstances - not always a chain of events thanks to i.Sense EC.B

Intelligent breakage detection i.Sense EC.B

Learn how the EC.B works in 82 seconds

- Module (EC = e-chain B = break detection) recognises breaks in individual chain links

- A rope is stretched through the e-chain, which picks up any change in length and reports it to the EC.B sensor.

- This detects chain breaks, switches off the system and prevents consequential damage

What technical components does i.Sense EC.B consist of?

The smart breakage monitoring technology in detail

How is the i.Sense EC.B sensor box mounted on the chain?

EC.B final assembled on a container crane

Konstantin Schmer explains the system

- The EC.B (EC = e-chain, B = breakage detection) module is installed at the moving end of the e-chain

- Special mounting brackets enable the EC.B sensor to be installed at the moving end of the e-chain

- The addition of an EC.M (EC = e-chain, M = motion) sensor to the breakage detection (EC.B) enables the step from pure condition monitoring to predictive maintenance. With the additional measured values (speed, acceleration, temperature), the system can predict a service life and indicate maintenance times

Intelligent breakage monitoring successfully realised

Industry 4.0: i.Sense EC.B in practice

When do I need a smart condition monitoring system like i.Sense EC.P?

When regular maintenance work requires complete production shutdown ...

When motion anomalies cannot be detected by humans in time ...

If maintenance work poses a health or safety risk ...

If maintenance costs are to be reduced and service life extended ...

If plants or machines need to be monitored frequently or continuously ...

If energy supply system travels are difficult to access or view ...

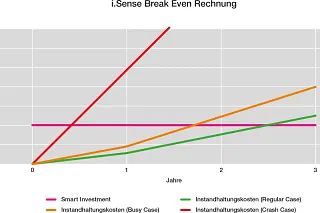

When does the purchase of i.Sense EC.B pay off?

It is often difficult to assess the financial benefits of safety systems, especially because the initial investment in a modern condition monitoring system naturally increases the maintenance costs at the beginning. That's why we analysed the entire period of use in a break-even analysis based on practical experience in an automotive production hall.

If all typical maintenance costs are offset against the average costs in the manufacturing industry in Germany of EUR 41.60 for one working hour, the benefit threshold of an i.Sense EC.B system is already reached in the 3rd year of use, even in the conservative scenario (regular case).

i.Sense EC.B as the basis for predictive maintenance

Always the optimum maintenance strategy with smart plastics from igus

Overview of smart plastics

Insight into the complete igus product portfolio for Industry 4.0

Content overview of this free brochure:

- Condition monitoring (i.Sense)

- Systems for condition monitoring

- Advantages of condition monitoring systems

- Application examples of condition monitoring

- Predictive maintenance (i.Cee)

- Systems for predictive maintenance

- Advantages of predictive maintenance systems

- Application examples for predictive maintenance

- Data flow in modern smart factory concepts

3D CAD portal for smart plastics

Designing intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already being used reliably in many hundreds of thousands of applications worldwide - from beverage vending machines and CNC machines to steelworks. Unsupported lengths can be bridged with ease and long travels are conceivable for a wide range of industries.

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h