Change Language :

Predictive maintenance with i.Cee:plus II: A whole lot of Industry 4.0 in one device

New i.Cee:plus module enables deep integration into customer networks and numerous IoT use cases

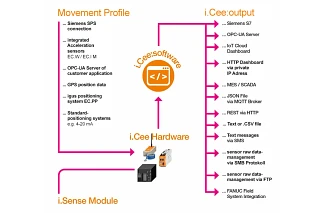

i.Cee - now also in the network environments and IoT concepts of our customers. The 2nd generation of the i.Cee:plus module creates the ideal conditions for predictive maintenance in line with customer requirements. This is because the possibility of seamless integration into the intended network environments of the respective applications means that a wide variety of Industry 4.0 use cases can be realised.

From preventive service management, which schedules regular maintenance depending on usage, to location-independent fault management, which immediately reports any unforeseen changes via various mobile channels, to comprehensive sensor data management, which even enables the integration of 3rd party cloud solutions, everything is possible. All information is aggregated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

This makes the 2nd generation i.Cee:plus module the centrepiece of every Industry 4.0 energy supply system, always with the aim of achieving maximum system and user safety as well as product service life.

Part number: IS.PLUS.01.01.0.BETA

What does predictive maintenance (i.Cee) mean at igus?

Only the intelligent networking of individual components creates a solid basis for predictive maintenance concepts. At igus, predictive maintenance is summarised under the term i.Cee.

The central element in this area is the i.Cee software. This software, in conjunction with sensors on the energy chain, the plain bearing bushing or a carriage, turns the products available from stock into smart products. This upgrade makes it possible to determine the maximum service life of your igus product, and the i.Cee system also indicates the perfect service time. Algorithms adjust the service life and the service time according to usage. With the software and a few sensors provided by us, standard products available from stock can be transformed into smart energy supply or bearing technology in no time at all.

You alone decide on the route & access of the data

Data transfer within your local company network (i.Cee:local) or via the secure cloud (i.Cee:cloud)

The white paper on predictive maintenance

Differentiates condition monitoring from predictive maintenance

In this white paper you will learn

- What does condition monitoring (i.Sense) mean for igus

- What is predictive maintenance (i.Cee) for igus

- What technology is behind both systems

- What do both systems offer for energy supply in industry

Industry 4.0: realised in practice

Customer applications with smart plastics

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h