Change Language :

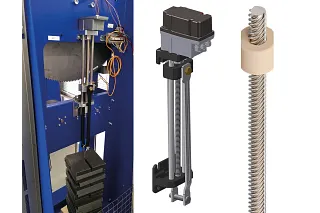

For precise linear movements: Aris actuator

Technical data:

- What was needed: Precise movement and positioning of the actuators without regular maintenance

- Requirements: Highest accuracy even under adverse environmental conditions, freedom from lubrication and maintenance, no adhesion of dirt and dust

- Products used: dryspin® threaded spindle from the standard range, lead screw nut in special geometry

- Success for the customer: A new series for precise travel, cost savings due to the elimination of maintenance, possible service life calculation with fast test bench results and greater customer interest due to unfamiliar threaded nut materials

High-precision linear drive with dryspin® spindle unit

Products used

Do you have questions about drylin® lead screw technology?

Our expert Thorben Hendricks will answer all your questions about drylin® lead screw technology. Simply fill in the contact form and we will take care of your enquiry. We look forward to hearing from you!

► Request contact online

► Arrange an appointment

► Expert support on request by phone or via video chat function

► Order a free sample

Contact us

Contact details

igus® UK01604 677240Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h