Change Language :

Selection table and design data for twisterchain guide troughs

New generation of twisterchain guide troughs

Reduce installation time and costs - increase service life!

With the Twister trough type 01, the previously time-consuming adjustment work is significantly decreased from 6 to 2 hours. As its construction consists almost entirely of plastic, it can help prolong the service life of your system while minimising noise. Available for all twisterchain models from the new and previous product range.

- Suitable for high dynamics thanks to full guidance of the upper run

- Quieter and smoother guidance in the trough thanks to continuous upper run guide

- Upper run is guided in the new plastic trough and supported across the entire width

- Pre-fitted delivery available

- Easy adjustment, alignment and handling

- Installation time reduced from 6 to 2 hours

Installation dimensions

X1 inner machine limit and X2 outer machine limit of the guide trough

| AR [mm] | X2 [mm] | X1 [mm] | depending on Bi [mm] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TC32 | 480 | 87.5 | 100 | 108 | 125 | 137.5 | 150 | ||||||||

| 400 | 480 | 270 | 250 | 250 | 220 | 210 | 200 | ||||||||

| 500 | 580 | - | 350 | 350 | 320 | 310 | 300 | ||||||||

| 600 | 680 | - | - | 450 | 420 | 410 | 400 | ||||||||

| TC42 | 87.5 | 100 | 108 | 125 | 137.5 | 150 | 162.5 | 168 | 175 | 187.5 | 200 | ||||

| 400 | 480 | 270 | 250 | 250 | 220 | 210 | 200 | 190 | 190 | 180 | - | - | |||

| 500 | 580 | - | 250 | 250 | 220 | 210 | 200 | 190 | 190 | 180 | 180 | 150 | |||

| 600 | 680 | - | - | 250 | 220 | 210 | 200 | 190 | 190 | 180 | 180 | 150 | |||

| TC56 | - | - | 125 | 137.5 | 150 | 162.5 | - | 175 | 187 | 200 | |||||

| 650 | 730 | - | - | - | 470 | 460 | 450 | 440 | - | 430 | 420 | 400 | |||

| 750 | 830 | - | - | - | - | 460 | 450 | 440 | - | 430 | 420 | 400 | |||

| 850 | 930 | - | - | - | - | - | 450 | 440 | - | 430 | 420 | 400 | |||

| 2808 | 50 | 68 | 75 | 87.5 | 100 | 108 | 125 | 137.5 | 150 | ||||||

| 400 | 480 | 290 | 280 | 270 | 270 | 250 | 250 | 220 | 210 | 200 | |||||

| 500 | 580 | 390 | 380 | 370 | 370 | 350 | 350 | 320 | 310 | 300 | |||||

| 600 | 680 | 490 | 480 | 470 | 470 | 450 | 450 | 420 | 410 | 400 | |||||

| 3808 | 50 | 68 | 75 | 87.5 | 100 | 108 | 125 | 137.5 | 150 | 162.5 | 168 | 175 | 187.5 | 200 | |

| 400 | 480 | 290 | 280 | 270 | 270 | 250 | 250 | 220 | 210 | 200 | 190 | 190 | 180 | 180 | 150 |

| 500 | 580 | 390 | 380 | 370 | 370 | 350 | 350 | 320 | 310 | 300 | 290 | 290 | 280 | 280 | 250 |

| 600 | 680 | 490 | 480 | 470 | 470 | 450 | 450 | 420 | 410 | 400 | 390 | 390 | 380 | 380 | 350 |

| 4008 | 50 | 65 | 75 | 100 | 112 | 125 | 137.5 | 150 | 162.5 | 175 | 187.5 | 200 | |||

| 650 | 730 | 540 | 530 | 520 | 500 | 490 | 470 | 460 | 450 | 440 | 430 | 420 | 400 | ||

| 750 | 830 | 640 | 630 | 620 | 600 | 590 | 570 | 560 | 550 | 540 | 530 | 520 | 500 |

Installation height

HF depending on bend radius of twisterchain guide trough

| R [mm] | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 400 |

|---|---|---|---|---|---|---|---|---|

| Series | HF Installation height [mm] | |||||||

| TC32 | 370 | 420 | 470 | 520 | 570 | 670 | - | - |

| TC42 | 380 | 430 | 480 | 530 | 580 | 680 | - | - |

| TC56 | - | - | 500 | - | 600 | 700 | 800 | 1000 |

| 2808 | 370 | 420 | 470 | 520 | 570 | 670 | - | - |

| 3808 | 380 | 430 | 480 | 530 | 580 | 680 | - | - |

| 4808 | - | - | 500 | - | 600 | 700 | 800 | 1000 |

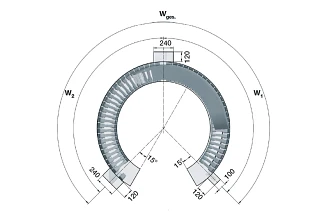

Rotation angle | W1 and Wtotal

| Wges. Rotation angle of system [°] | W1Angle of lower run [°] |

|---|---|

| 90° | 45° |

| 180° | 90° |

| 270° | 135° |

| 360° | 180° |

Rotation angle

W2 angle of upper run trough [°] twisterchain guide trough

| AR | Series | R [mm] | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 400 |

|---|---|---|---|---|---|---|---|---|---|---|

| [mm] | W2 Rotation angle[°] | |||||||||

| 400 | TC32/TC42/2808/3808 | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | |

| 500 | TC32/TC42/2808/3808 | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | |

| 600 | TC32/TC42/2808/3808 | 135° | 135° | 135° | 135° | 90° | 90° | 90° | 90° | |

| 650 | TC56/4008/TC42 | 135° | 135° | 135° | 135° | 90° | 90° | 90° | 90° | |

| 750 | TC56/4008/TC42 | 135° | 135° | 135° | 135° | 135° | 135° | 90° | 90° | |

| 850 | TC56/4008/TC42 | 135° | 135° | 135° | 135° | 135° | 135° | 135° | 135° |

AR = outer radius of chain

IR = inner radius of chain

R = bend radius of chain

X1 = inner machine limit

X2 = outer machine limit

HF = total height of trough

W1 = angle of upper run trough

W2 = angle of lower run trough

Wtotal = rotation angle of the system

Order example for a twisterchain guide trough

R - bend radius, add the corresponding value

Bi - inner width, add the corresponding value

Outer radius

Rotation angle of the application (90°, 180°, 270°, 360°)

Trough design

Guide trough - selected series

Further order examples

Complete trough

Part No. 94008.31.180.600/06.250

Lower run trough only

Part No. 94008.30.180.600/06.250

Upper and lower run trough without base support

Part No. 94008.32.180.600/06.250

| Part No. Series | Outer radius AR [mm] | Rotation angle from-to α [°] | Part No. Complete trough | Part No. Upper/lower run trough | Part No. Lower run trough |

|---|---|---|---|---|---|

| TC32/TC42/2808/3808 | 400 | 0 - 90° | 9XXX.31.90.400/Bi.R | 9XXX.32.90.400/Bi.R | 9XXX.30.90.400/Bi.R |

| 90° - 180° | 9XXX.31.180.400/Bi.R | 9XXX.32.180.400/Bi.R | 9XXX.30.180.400/Bi.R | ||

| 180° - 270° | 9XXX.31.270.400/Bi.R | 9XXX.32.270.400/Bi.R | 9XXX.30.270.400/Bi.R | ||

| 270° - 360° | 9XXX.31.360.400/Bi.R | 9XXX.32.360.400/Bi.R | 9XXX.30.360.400/Bi.R | ||

| 500 | 0 - 90° | 9XXX.31.90.500/Bi.R | 9XXX.32.90.500/Bi.R | 9XXX.30.90.500/Bi.R | |

| 90° - 180° | 9XXX.31.180.500/Bi.R | 9XXX.32.180.500/Bi.R | 9XXX.30.180.500/Bi.R | ||

| 180° - 270° | 9XXX.31.270.500/Bi.R | 9XXX.32.270.500/Bi.R | 9XXX.30.270.500/Bi.R | ||

| 270° - 360° | 9XXX.31.360.500/Bi.R | 9XXX.32.360.500/Bi.R | 9XXX.30.360.500/Bi.R | ||

| 600 | 0 - 90° | 9XXX.31.90.600/Bi.R | 9XXX.32.90.600/Bi.R | 9XXX.30.90.600/Bi.R | |

| 90° - 180° | 9XXX.31.180.600/Bi.R | 9XXX.32.180.600/Bi.R | 9XXX.30.180.600/Bi.R | ||

| 180° - 270° | 9XXX.31.270.600/Bi.R | 9XXX.32.270.600/Bi.R | 9XXX.30.270.600/Bi.R | ||

| 270° - 360° | 9XXX.31.360.600/Bi.R | 9XXX.32.360.600/Bi.R | 9XXX.30.360.600/Bi.R | ||

| TC56 /4008 | 650 | 0 - 90° | 9XXX.31.90.650/Bi.R | 9XXX.32.90.650/Bi.R | 9XXX.30.90.650/Bi.R |

| 90° - 180° | 9XXX.31.180.650/Bi.R | 9XXX.32.180.650/Bi.R | 9XXX.30.180.650/Bi.R | ||

| 180° - 270° | 9XXX.31.270.650/Bi.R | 9XXX.32.270.650/Bi.R | 9XXX.30.270.650/Bi.R | ||

| 270° - 360° | 9XXX.31.360.650/Bi.R | 9XXX.32.360.650/Bi.R | 9XXX.30.360.650/Bi.R | ||

| 750 | 0 - 90° | 9XXX.31.90.750/Bi.R | 9XXX.32.90.750/Bi.R | 9XXX.30.90.750/Bi.R | |

| 90° - 180° | 9XXX.31.180.750/Bi.R | 9XXX.32.180.750/Bi.R | 9XXX.30.180.750/Bi.R | ||

| 180° - 270° | 9XXX.31.270.750/Bi.R | 9XXX.32.270.750/Bi.R | 9XXX.30.270.750/Bi.R | ||

| 270° - 360° | 9XXX.31.360.750/Bi.R | 9XXX.32.360.750/Bi.R | 9XXX.30.360.750/Bi.R | ||

| 850 | 0 - 90° | 9XXX.31.90.850/Bi.R | 9XXX.32.90.850/Bi.R | 9XXX.30.90.850/Bi.R | |

| 90° - 180° | 9XXX.31.180.850/Bi.R | 9XXX.32.180.850/Bi.R | 9XXX.30.180.850/Bi.R | ||

| 180° - 270° | 9XXX.31.270.850/Bi.R | 9XXX.32.270.850/Bi.R | 9XXX.30.270.850/Bi.R | ||

| 270° - 360° | 9XXX.31.360.850/Bi.R | 9XXX.32.360.850/Bi.R | 9XXX.30.360.850/Bi.R |

Contact us

Contact details

Justin Leonard01604 677240Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h