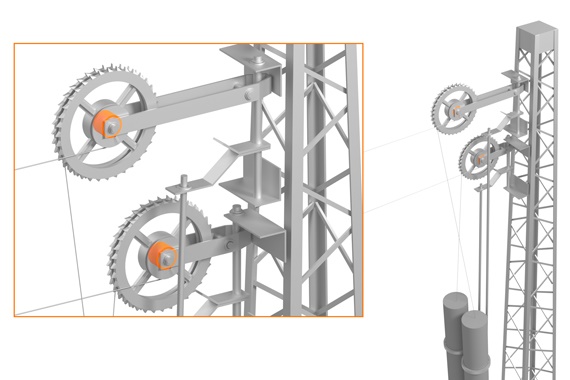

Corrosion-free plain bearing for wheel tensioners

Profile

- What was required? plain bearings for wheel tensioners

- Manufacturing process: injection moulding

- Requirements: weather-resistant and robust components

- Material: iglidur J and P210

- Industry: railway technology – infrastructure

- Success for the customer: service life of the polymer plain bearings is predictable

Whether in town or along a high-speed route - overhead cables with automatic compensation systems in the form of wheel tensioners are needed everywhere. They are continuously exposed to heat or cold due to weather conditions. To make sure that bearings in the wheel tensioners work in these application conditions, iglidur plain bearings made of high-performance polymers are used. They contain incorporated solid lubrication and therefore do not require additional lubrication. As a consequence, maintenance is minimised and movements at the bearings are always smooth.

The iglidur high-performance polymers are light and corrosion-free due to their material. They are tested extensively in the igus test lab and therefore have optimal friction and wear properties as well as a predictable service life. By means of free igus online tools, you can therefore predict exactly how long a bearing will last under certain conditions. A further advantage of the polymer bearings is that they can be used on almost all shafts. Therefore, both hardened and soft shaft materials are possible.