Knowledge at the touch of a button: first smart complete sets in igus online shop

Ready-to-install solutions for predictive maintenance selected in seconds and ordered online

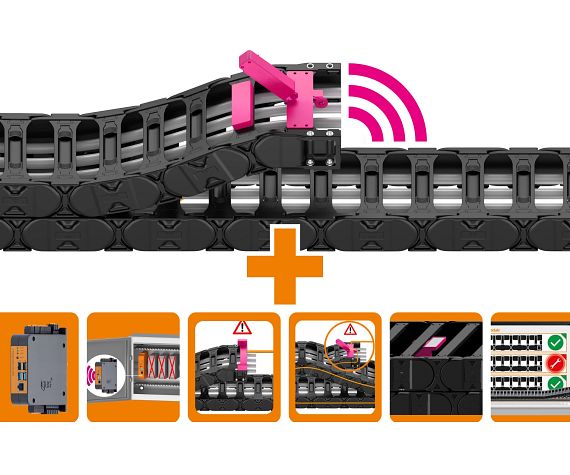

smart plastics make your energy supply system intelligent ... at the touch of a button. Now you can conveniently order the smart complete package for condition monitoring and predictive maintenance online. The appropriate components are suggested based on your existing e-chain. All you have to do is specify the application parameters, such as cable projections or control cabinet position, and you have the ready-made complete set for retrofitting ... all this including price, delivery time and parts list.i.Sense EC.P and EC.B are used for condition monitoring, as is the new i.Sense:modul II, which can process several sensor signals simultaneously. The new i.Cee:plus II module then evaluates all data for predictive maintenance management and optimally provides it to the user in the associated i.Cee dashboard.

Go straight to the online shop

Tech up

- i.Sense condition monitoring configuration and sensor data download over many channels (USB, LAN, WLAN, Bluetooth, etc.) to various terminal devices

- SMS/e-mail alarm

- Increased connectivity for absolute transparency for predictive maintenance – "anytime, anywhere, anyhow" (network connections: dashboard on local intranet, connection to PLC and system monitor, etc.)

Cost down

- No project planning costs, no coordination loops

- No minimum order quantity - cost-effective system price from 1 piece

- All sensors for condition monitoring connected to the i.Sense module in the switch cabinet

- Use predictive service management to avoid unplanned plant downtimes and the resultant costs

Proof

- Ongoing test series in the industry's largest test laboratory for dynamic

power transmission systems - Operational since January 2021 in Poland on a

440m travel path

Sustainability

- Reduce physical travelling costs with remote connection

- Unplanned service operations can be prevented - eliminating 100km of travel saves about 3.6kg of CO²

What does condition monitoring (i.Sense) do?

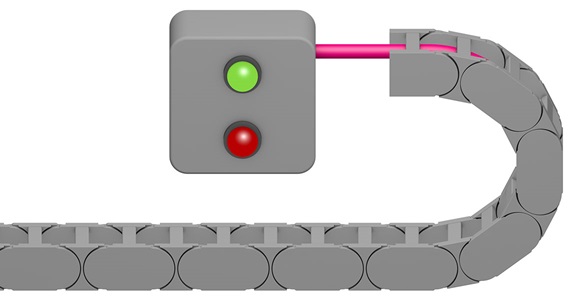

Condition monitoring is the fastest, simplest way to combine many igus products to form a self-monitoring smart plastics product. Sensors are mounted to measure values (such as temperature, forces, and sound waves/vibrations) within pre-defined limits. If the limits are exceeded the operator gets notified. This information provides the basis for taking subsequent steps, such as maintenance or system shutdown. If required, values outside defined limits can trigger a system shutdown to avoid expensive damage. At igus, we use the term "i.Sense" to refer to condition monitoring.Find out all the details about condition monitoring here

What does igus predictive maintenance (i.Cee) mean?

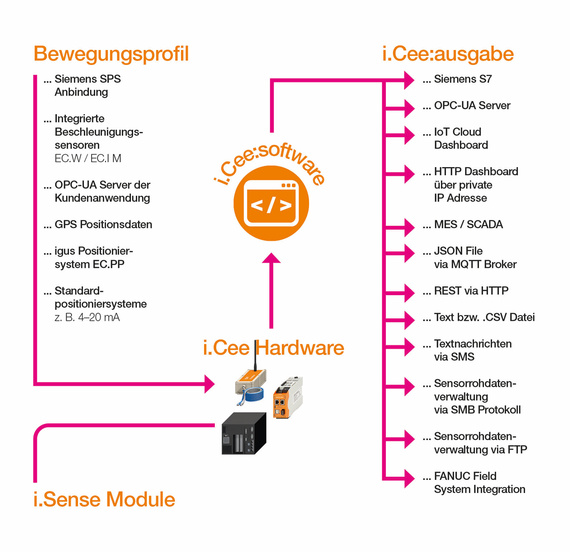

Smart networking of individual components creates the solid foundation for predictive maintenance concepts. At igus, we call our predictive maintenance system i.Cee.The central element of this system is the i.Cee software. This software, combined with sensors on the energy chain, the plain bearing or a linear carriage, transform stock products into smart products. This upgrade enables you to determine the maximum service life of your igus product and the i.Cee system specifies the perfect time for servicing. Algorithms adjust the service life and service time according to usage. The software we provide plus a few sensors transform standard products available from stock into a smart energy supply system or smart bearing technology in no time.

Learn all about predictive maintenance here

Industry 4.0: real-world examples

Customer applications with smart plastics

Aluminium oxide production

"If chain movement is excessively hindered by dust or dirt, push/pull monitoring shuts down the system before any damage can occur."

Aluminium Oxid Stade GmbH (AOS)

Aluminium Oxid Stade GmbH (AOS)

To the application report

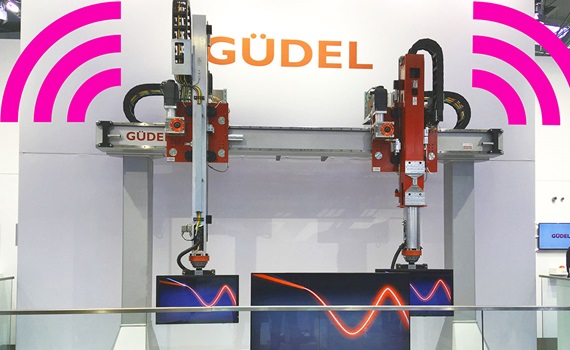

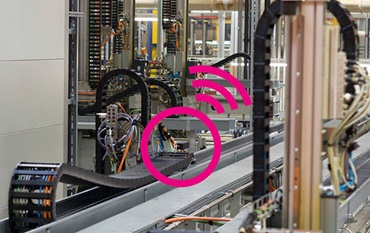

Linear robots

Integration of smart plastics sensors into the energy supply allows data supply to the customer's condition monitoring system.

Güdel Deutschland GmbH

Güdel Deutschland GmbH

To the application report

More smart applications

Here you can find further successful application examples from our smart plastics customers.

smart plastics application examples

The igus® white paper on predictive maintenance

Clarifies the distinction between condition monitoring and predictive maintenance

In this white paper, you will find out:

- What igus® condition monitoring (i.Sense) means

- What igus® predictive maintenance (i.Cee) means

- What technology is behind both systems

- What the two systems offer industrial energy supply

Go to free download

Smart consulting tool

Learn more

Smart brochure

Learn more