Change Language :

Apiro: the modular drive gear box system

Individual applications can be implemented with the drygear® Apiro modular drive gearbox system in an extremely modular and cost-effective manner. Possible applications can be in packaging, food, medical and many other industries. Lane adjustments, pusher tasks, gearboxes with different gear ratios, slewing rings and rotary axes can be used there. The modular gearbox system can be motorised or used for manual adjustments.

The Apiro modular system offers different gear ratios but also length variants, so that there are endless possibilities for combinations and applications.

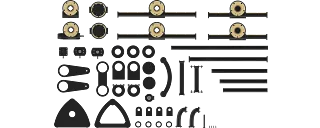

The modular drive gearboxes and components at a glance

Send us your request

Design your own modular gearbox system

1. Describe your individual application The modular gearbox system enables a wide range of automation applications with simple and complex motion sequences.

2. We select the optimal components for you Our experts will find the optimal solution for you with as few components as possible.

3. Easy installation The gearbox construction kit is modular in design, so that different kinematics can be implemented by simply plugging them together

Versatile and flexible applications with modular drive gearbox systems

For simple and complicated movements

Cost-effective modular gearbox system with durable components

Downloads

drygear® Apiro data sheet

EU_2019_robolink_Datenblatt_Apiro_MAT0074626.20.pdfAssembly instructions

Instruction: Cantilever axis

robolinkAPIRO_canilever_axis.pdfInstruction: Multi-functional profile

robolink APIRO_multi-functional_profile.pdfInstruction: Cantilever axis with drive pin

robolink APIRO_set_.pdf20 new application examples for robotic modular gearbox systems

iDeas templates for easy rebuilding

The Apiro® robotic modular gearbox system is now available with 20 new iDeas templates so that you can easily recreate structures yourself.

Three steps to the finished gearbox

1. Select an automation solution

2. Download parts lists and CAD data

3. Simply recreate the automation solution

Apiro® starter kit

One robot gear set for eight systems

Apiro® (Greek for "infinite") modular robot gearbox system, now available as a starter kit. Instructions help you assemble your own robot.

Contact us

Contact details

Adam Sanjurgo07977 018171Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h