Change Language :

Cleanroom solutions up to ISO Class 1

Display robots or in pick-and-place applications in semiconductor manufacturing and microelectronics

Cleanroom environments impose exceptionally strict demands on the abrasion resistance of moving components, as even the smallest particle release can compromise sensitive processes, damage products or lead to costly production interruptions.

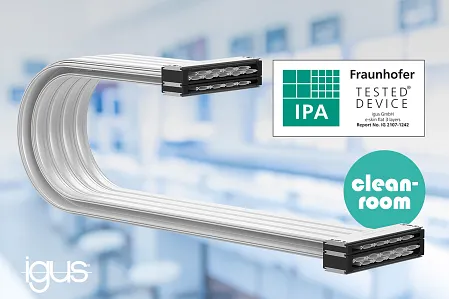

To meet these challenges, igus® designs and validates its high‑performance polymer components in a dedicated in‑house cleanroom laboratory, where materials and systems are tested under realistic operating conditions. For additional verification and independent certification, our products undergo further evaluation by the Fraunhofer Institute, ensuring reliable, data‑driven proof of cleanroom suitability.

Cleanroom solutions | compatible products

Energy chains

e-chains® in a cleanroom environment have to be abrasion-resistant as airborne particles can be released and can contaminate the cleanroom.

Cables and hoses

Cables with IPA ISO class 1 and 2 are available ready for connection, suitable for manufacturers such as Bosch Rexroth, Festo, Parker and Siemens

Linear guides

Within our product range of dry-operating linear guide systems, we offer four models that are certified for use in ISO class 6 to 3 cleanrooms.

Slewing ring bearings

The sliding elements of the PRT-04-100 slewing ring is made of iglidur J which minimises particle emissions, so they can be used in cleanroom applications.

e-skin® cleanroom energy chain

The e-skin® energy chain is specifically produced for cleanroom applications. Variety of variants to choose from depending on the application

Configurator

Are you unsure which energy supply is the right one for your application?

You can find the suitable solution with just a few clicks.

Free white paper

Energy supply for the cleanroom

In this white paper, you will learn how you can use the right energy supply in the cleanroom to

- increase system efficiency

- generate higher production line yields

- use energy supply more sustainably

Successful in use in cleanroom applications

cleanroom product brochure

Cleanroom classes of our products as well as information on RoHs and ESD.

Download now

Information on ESD

More about the igus® material igumid® for ESD applications.

Frequently asked questions

As the quality requirements for cleanroom technology applications are constantly growing, igus® is continuously working on improving its products. For this purpose, igus® has been carrying out tests for cleanroom suitability in its own test laboratory since 1997. In addition, appropriate products are tested externally by the Fraunhofer Institute.

The cleanroom suitability of our iglidur® plain bearings is determined on the basis of the wear particles released in the application. The size and quantity of the released wear particles depend on:

• the respective pairing of shaft and bearing material

• further parameters such as load, speed etc.

Therefore, there are no clearly defined cleanroom materials for our plain bearings, but instead they depend on their use.

Contact us

Contact details

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h