Change Language :

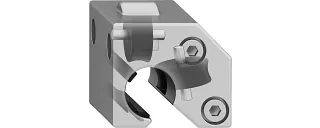

Hybrid roller bearings for drylin® W

With the unique combination of lubrication-free plain and roller bearings, igus® offers a particularly smooth and cost-effective solution for linear guides. The technology, which is ideal for manual adjustments, enables a silent operation with applications such as machine doors, protective doors and moveable control panels.

Due to the integrated rollers, low drive forces with a friction value of 0.1 µ can be achieved. The sliding elements made of iglidur® plastic absorb lateral and misuse forces. The roller bearings perfectly match various hard-anodised aluminium profiles from the drylin® W linear system.

Roller bearing options

What are roller bearings?

Roller bearings are used when the movement has to result in the lowest possible resistance to rolling because roller bearings have a low frictional resistance. They are also known as rolling bearings.

igus combines roller bearings with plain bearings, taking full advantage of their consolidated benefits. There are different types of roller bearings, such as axial roller bearings or tapered roller bearings.

Frequently asked questions about roller bearings

roller bearings use 2 different technologies, linear and roller technology. This is unlike classic roller bearings.

The additional liners installed in the carriage give the hybrid roller bearings more grip and stability, and weight is transmitted to the shaft more evenly. This extends the service life of shaft and rollers and allows greater maximum loads.

There are multiple applications for using drylin® roller bearings. Applications where there is a requirement to reduce displacement resistance, sliding doors, machine guides as some examples.

Contact us

Contact details

Lee Wilkins07736 269217Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h