Cost-effective automation with maintenance-free cartesian and delta robots

The drylin® linear robots are based on the lubrication-free drive and linear technology from igus®. As a manufacturer and supplier of all required axes, motors, energy chains, cables and hoses, igus® offers both fast delivery of pre-configured linear robot kits within 24 hours and custom solutions. The drylin® linear robots can be conveniently configured and assembled online as well as designed on site by our experts.

Typical applications for linear robots include pick-and-place solutions, measurement and test automation, marking applications, assembly cells, sorting machines, safety technology, laboratory and analytical technology, medical technology, handling, automation and positioning.

Would you like more information about drylin® linear robots or do you need an individual consultation? Our experts will be happy to get in touch with you.

Options of the igus® linear robots

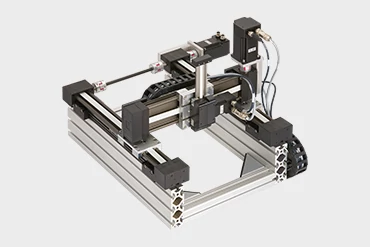

Gantry robots

- Drive: toothed belt/racks

- Motor: NEMA stepper motors

- Line robots, low-profile linear robots or room linear robots

- Individually configurable or available as a construction kit

- Find out more

Delta robot

- Modular system for simple assembly or pre-assembled

- Lightweight

- Self-lubricatingtoothed belt axes

- Ready to connect with stepper motors and dryve D1 motor control system

- Find out more

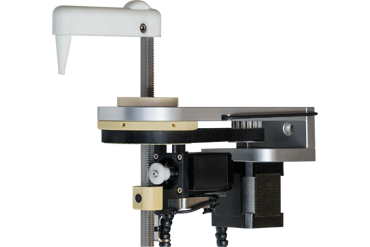

drylin® - lift/swivel unit HSQ

- Especially light due to polymer and hard anodised aluminium

- Ready to install with NEMA11 stepper motor

- Square profile with hollow chamber for supply lines and media

- Modular design

- Find out more

Maintenance-free linear robots in the applications of our customers

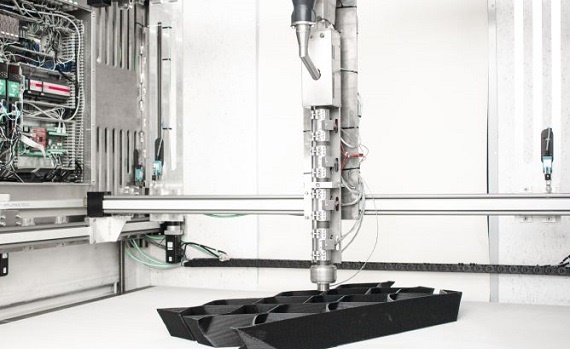

Tailored linear robot systems for mobile XXL-3D printers

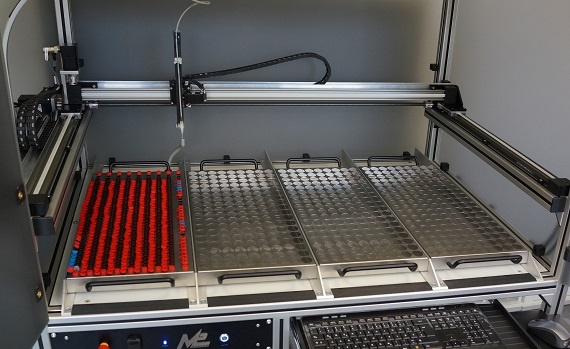

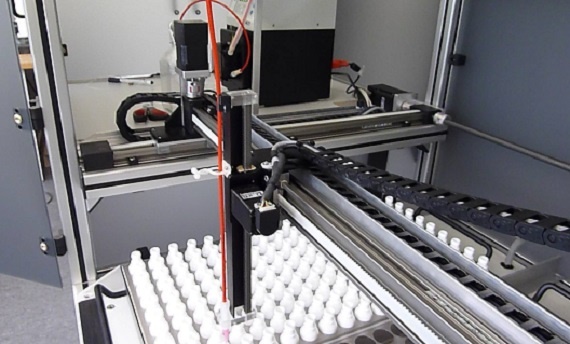

Linear robots in filling machines of biochemical liquids

Further application examples with linear robots

What is a linear robot?

Linear robots are industrial robots, consisting of a combination of several linear axes. They help to implement a multi-dimensional movement and are used for positioning tasks, automation and as measuring stations. Linear robots are available in numerous designs, including line robots, low-profile linear robots and room linear robots.- Line robots are used in vertical working planes whereby a linear axis mounted on a linear carriage travels on the main axis.

- Low-profile linear robots or surface linear robots are based on a linear axis system that can be moved in the XY direction.

- Room linear robots are typically 3-axis linear robots with XYZ strokes, whereby additional axes are possible.

What is a delta robot?

Delta robots are industrial robots with at least three arms, which are either fixed to a base with universal joints or, in the case of drylin delta robots, to toothed belt axes. The flange star connected via spherical bearings with the arm-axes moves in X, Y and Z directions in such a way that it allows high precision. The arms of delta robots are very light, which reduces the inertia and allows high achievable speeds and accelerations.This type of pick and place robots is often used in factories for packaging and assembly.

What is a lift/swivel unit?

The lift/rotate unit is a space-saving pick and place robot based on a rack drive with a coated aluminium profile and a slewing ring with integrated toothing for receiving the toothed belt. Powered by a Nema motor, the lift/rotate unit can perform lifting and pivoting movements. The guide rod is at the same time the drive rod, whereby this handling device can move into very small installation spaces.Due to the compact design, the lift/rotate unit offers versatile and flexible application possibilities in the handling of small parts.

Frequent fields of application:

- Pipetting technology

- Laboratory technology

- Analysing technology

- Medical technology

Configure your custom lead screw linear system online

- Customise your drive system in just a few steps

- Optional configuration of an individual drive pin

- Automatic generation of a 3D model of the linear system

- Export of the linear system in many different 2D and 3D formats

- 2D dimensional drawing of the module as a PDF

- Download parts list as PDF file

- Add to shopping cart and submit order or request a quotation online