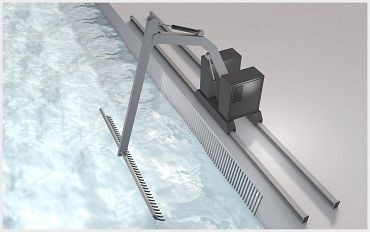

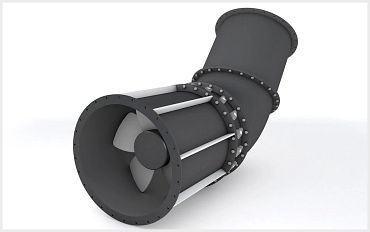

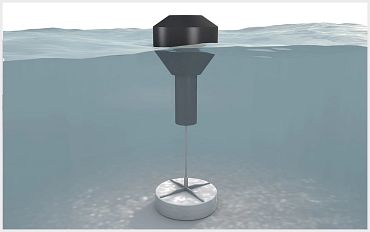

Hydro energy is a specific form of energy drawn from the power of water or hydro. It is the force of the water that creates the motion and therefore creates the power.

One of the key advantages of hydro energy is the fact it is a sustainable source of energy. As the energy is created from the water cycle, which as we all know is fuelled by the sun, it is a clean energy source and therefore renewable.

Like everything there are a few disadvantages such as limited amounts of water at certain points in the year, it can be a more expensive energy source and we are limited to where these hydro energy plants can be located.

Monday to Friday from 8am - 8pm.

24h