Contact

igus® Ltd.

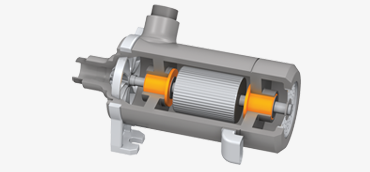

Cost-effective alternative to conventional lead screw drives made of metal

Individual design, uncomplicated system integration, short delivery times

Wide variety of materials and complete absence of a need for lubrication or maintenance

Almost silent operation, ideal for small installation spaces

Monday to Friday from 8am - 8pm.

24h